Experience Sharing

2022 Quarter 2 Issue 47

Automation in re-engineered material industry

Following the new applications driven by latest scientific and technological development and the outbreak of lazy economy, the rise of new consumer goods and the market demand for smart appliances are growing rapidly. Intelligent products are entering the daily life of more people. The huge demand has attracted more and more enterprises to enter the intelligent appliance market. In order to attract the attention of consumers and keep a place in the market, manufacturers must constantly develop new products, optimize processes and meet more personalized needs of consumers. The use of automatic equipment in production line can effectively control the cost, improve the production efficiency, ensure the product quality and improve the overall competitiveness of the enterprise.

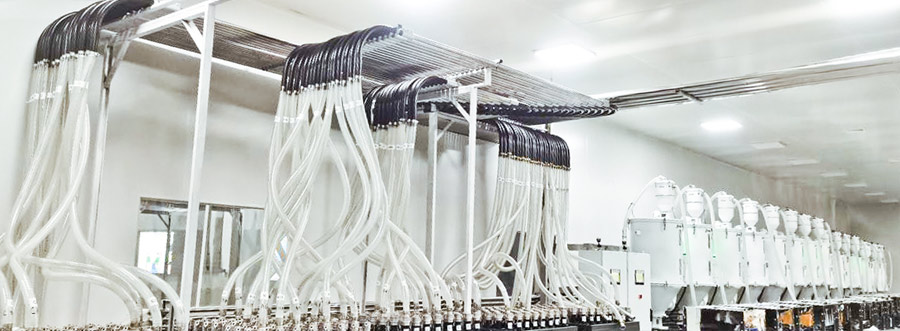

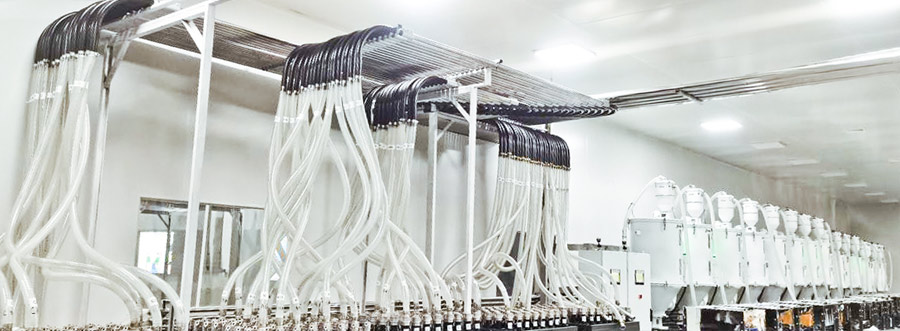

An re-engineered material company in Jiangxi province is a large enterprise covering the design, manufacturing and sales of electronic products such as intelligent household appliances, medical treatment and intelligent remote controllers. It is a remote controller supplier designated by many well-known brand (Midea, Changhong, Skyworth, Konka, Siemens, etc.). In 2021, the company worked together with Shini group and ordered more than 50 sets of ST3/ST5 small and medium-sized robots from Shini for fully automatic injection molding of plastic parts. In the same period, Shini has also supplied other centralized system (central raw material processing system, central chilled water supply system, central power distribution system, central compressed air supply system and intelligent logistics system) to help the customer build an intelligent injection molding factory and realize the concept of intelligent manufacturing. After the equipment is put into use, the operation of the equipment is stable, the cycle coordination with the injection molding machine is unified, the production efficiency and quality are significantly improved, and the customers are very satisfied.

The ST3/ST5 series robot is designed to remove products/sprue from injection molding machine. Customers can choose single/dual arm(s) robot for use with 2-plate mold, 3-plate mold or hot runner system. The robots have demonstrated the concept of industry 4.0 and capable of aligning, stacking, quality checking and insert placing. It is suitable for injection molding machine under 3600T clamp force.

An re-engineered material company in Jiangxi province is a large enterprise covering the design, manufacturing and sales of electronic products such as intelligent household appliances, medical treatment and intelligent remote controllers. It is a remote controller supplier designated by many well-known brand (Midea, Changhong, Skyworth, Konka, Siemens, etc.). In 2021, the company worked together with Shini group and ordered more than 50 sets of ST3/ST5 small and medium-sized robots from Shini for fully automatic injection molding of plastic parts. In the same period, Shini has also supplied other centralized system (central raw material processing system, central chilled water supply system, central power distribution system, central compressed air supply system and intelligent logistics system) to help the customer build an intelligent injection molding factory and realize the concept of intelligent manufacturing. After the equipment is put into use, the operation of the equipment is stable, the cycle coordination with the injection molding machine is unified, the production efficiency and quality are significantly improved, and the customers are very satisfied.

ST5 servo driven robot appearance

Experience Sharing

If you want to read other articles, back to2022 Quarter 2 Issue 47.