Experience Sharing

2022 Quarter 2 Issue 47

The Plastics Auxiliary Equipment Used in Agricultural Products

A well-known enterprise in Hunan mainly produces large non-standard storage boxes used in agriculture. Considering the production, to better meet the strong demands of the industrial chain, this company chose Shini Plastics to become its partner after a comprehensive assessment and evaluation. Shini designed the whole plant solution for the plastic auxiliary equipment for the customer, including the central material processing system, robot, mold temperature controller, and hot runner products. This solution can work with 24 sets of injection molding machines in total, and there are 3 sets of 1400T, 10 sets of 2100T, and 11 sets of 2400T IMM.

The whole material processing system adopts the autoloader of the big bag to transfer materials in the big bag to the plastics dryer by negative pressure, radically improving the traditional manual operation mode and significantly reducing the discharge workload of the big bag. The materials from the big bag will enter the dryer after being heated up by the hot air to remove the moisture of the particles to achieve pre-drying and meet the injection process demands. After drying, the plastics under the action of the blower will be sent to different injection molding machines via the central material distribution station. The operator can switch the conveying pipes flexibly according to actual process requirements, thus achieving a high degree of flexibility and less human operation. It only needs manually change the plastics and set the control parameters during material replacement. The material selection is simple that can be finished in a few minutes. If it selects the wrong plastics, the system will identify automatically to realize unmanned operation. After the system operates, it only needs one person to work in the later stage of the process to improve productivity, shorten the production cycle and improve the workshop environment.

The automation solution provides three axes servo-driven robot ST3 according to different product demands, which is equipped with other end rotation axis and fixtures based on product shapes and processes. It conforms to the industrial 4.0 specification and meets the most complex applications, such as mold replacement, stacking, etc. The flexible multi-degree of freedom motion helps achieve a complex and optimized taking-out method and path, suitable for injection moulding machines under 3600T clamp force.

The mould temperature controller is equipped with a cooling/heating mold temperature controller with a wider adjustment range than traditional water heaters. The temperature range is 7 ℃ ~120 ℃, which can meet most working demands. This model has accurate temperature control and can heat up and cool the equipment to the required temperature. Besides, it can control different temperatures of the machine to improve the IMM’s productivity and product quality.

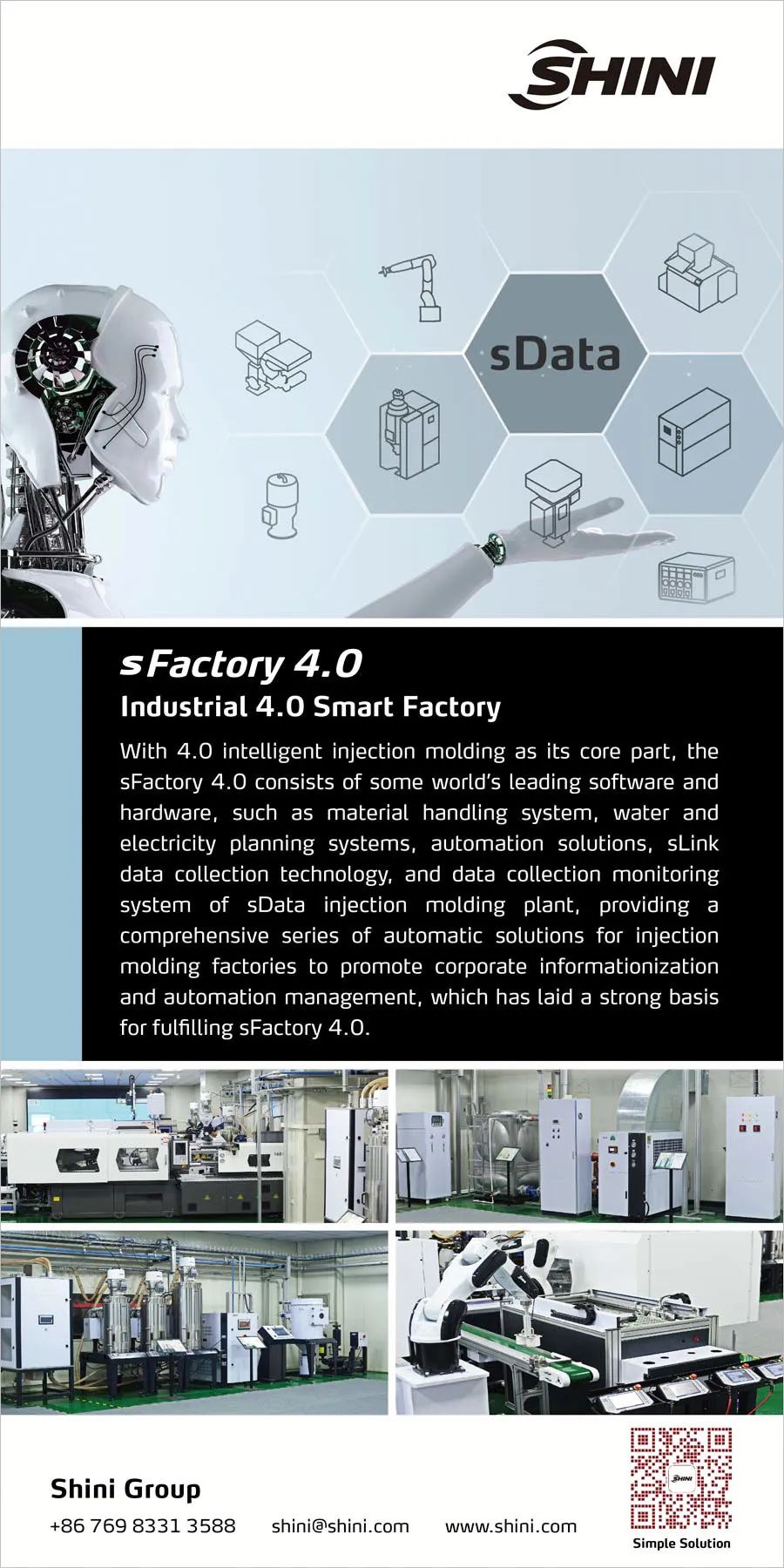

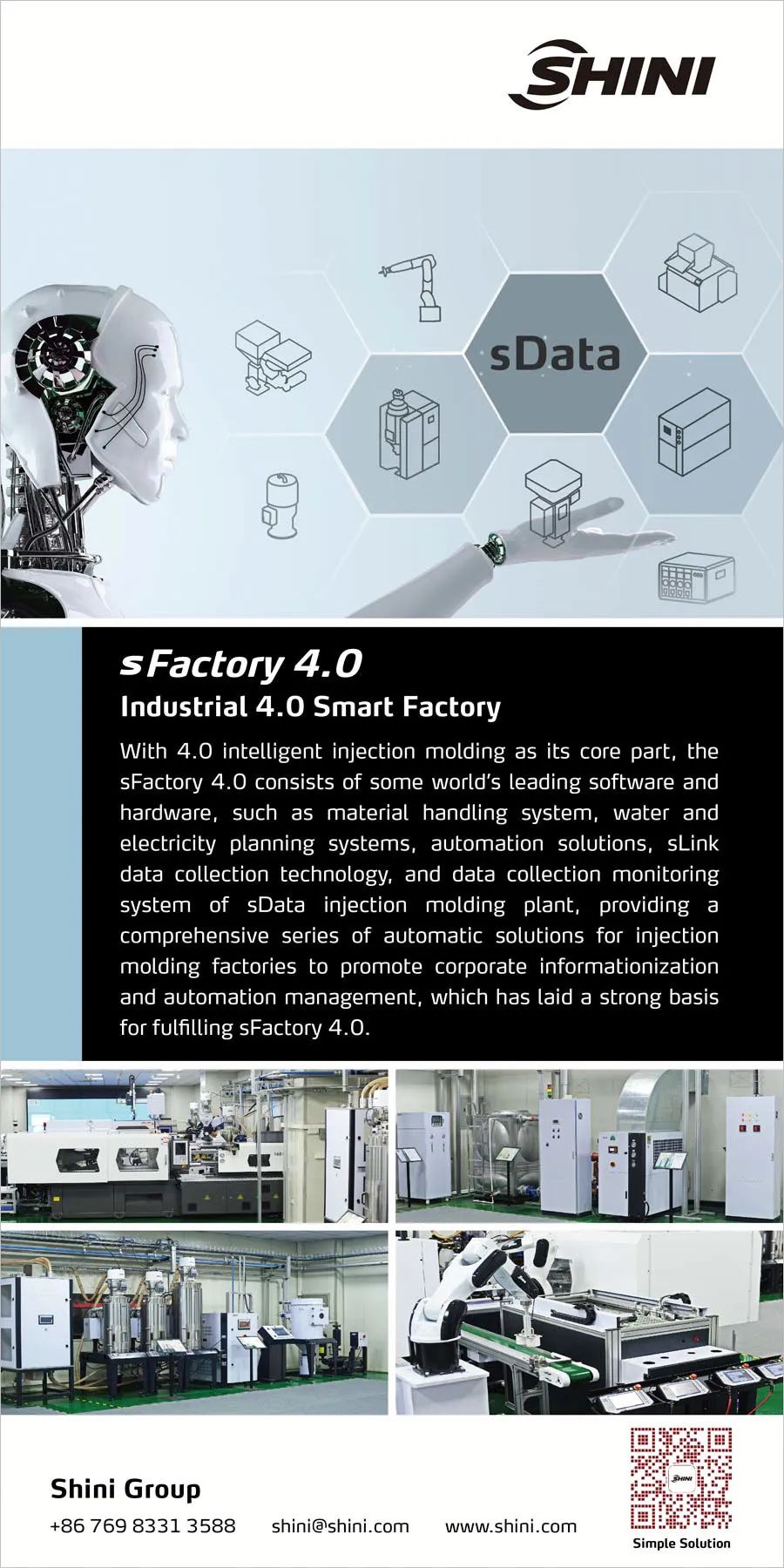

Established in 1969, Shini has experienced over 53 years of development. Now it offers eight series of products to the market through consistent research and progress, covering plastic material processing (dehumidification & drying, conveying, mixing, etc.), mold temperature control, water treatment (cooling water and chilled water system), plastic recycling and reusing, robot, hot runner, and systematic solution, as well as the whole process of the injection molding production. In the future, the era driven by the data is coming toward us, and the data from production, running equipment, etc., will push informatization progress. Currently, Shini is launching the smart injection moulding plant to the market, and it can provide an integrated intelligent whole plant solution of the auxiliary equipment based on digitalization and informatization. In addition, Shini auxiliary equipment can match the systematic plans well in practice to make all develop in-depth and expand in scope, providing the market with one-stop, simple, and practical solutions.

The whole material processing system adopts the autoloader of the big bag to transfer materials in the big bag to the plastics dryer by negative pressure, radically improving the traditional manual operation mode and significantly reducing the discharge workload of the big bag. The materials from the big bag will enter the dryer after being heated up by the hot air to remove the moisture of the particles to achieve pre-drying and meet the injection process demands. After drying, the plastics under the action of the blower will be sent to different injection molding machines via the central material distribution station. The operator can switch the conveying pipes flexibly according to actual process requirements, thus achieving a high degree of flexibility and less human operation. It only needs manually change the plastics and set the control parameters during material replacement. The material selection is simple that can be finished in a few minutes. If it selects the wrong plastics, the system will identify automatically to realize unmanned operation. After the system operates, it only needs one person to work in the later stage of the process to improve productivity, shorten the production cycle and improve the workshop environment.

The automation solution provides three axes servo-driven robot ST3 according to different product demands, which is equipped with other end rotation axis and fixtures based on product shapes and processes. It conforms to the industrial 4.0 specification and meets the most complex applications, such as mold replacement, stacking, etc. The flexible multi-degree of freedom motion helps achieve a complex and optimized taking-out method and path, suitable for injection moulding machines under 3600T clamp force.

The mould temperature controller is equipped with a cooling/heating mold temperature controller with a wider adjustment range than traditional water heaters. The temperature range is 7 ℃ ~120 ℃, which can meet most working demands. This model has accurate temperature control and can heat up and cool the equipment to the required temperature. Besides, it can control different temperatures of the machine to improve the IMM’s productivity and product quality.

Established in 1969, Shini has experienced over 53 years of development. Now it offers eight series of products to the market through consistent research and progress, covering plastic material processing (dehumidification & drying, conveying, mixing, etc.), mold temperature control, water treatment (cooling water and chilled water system), plastic recycling and reusing, robot, hot runner, and systematic solution, as well as the whole process of the injection molding production. In the future, the era driven by the data is coming toward us, and the data from production, running equipment, etc., will push informatization progress. Currently, Shini is launching the smart injection moulding plant to the market, and it can provide an integrated intelligent whole plant solution of the auxiliary equipment based on digitalization and informatization. In addition, Shini auxiliary equipment can match the systematic plans well in practice to make all develop in-depth and expand in scope, providing the market with one-stop, simple, and practical solutions.

Experience Sharing

If you want to read other articles, back to2022 Quarter 2 Issue 47.