Special Reports

2013 Quarter 4 Issue 17

Modular Application of Dehumidifying Dryer

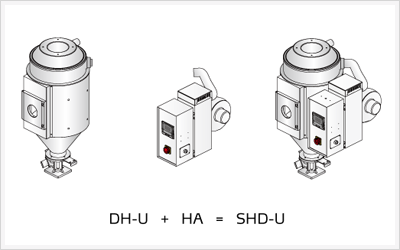

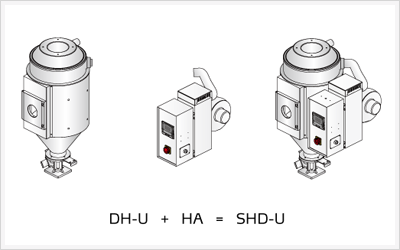

In order to reduce inventories and operation cost, to offer rapid supply of equipment and to operate efficiently, Shini will launch 22 kinds of hot air dryer HA whose drying air volume is 30~4000m3/h. HA which consists of blower, heater and controller, provides dry air and heat the air to set temperature. By being flexibly combined with heat-preservation hopper DH-U of different capacities, HA can become hopper dryers which have the same function with hopper dryer SHD-U to dry non-absorbent plastic material and preheat plastic material before molding.

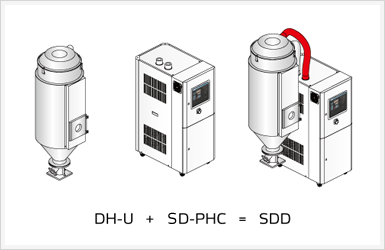

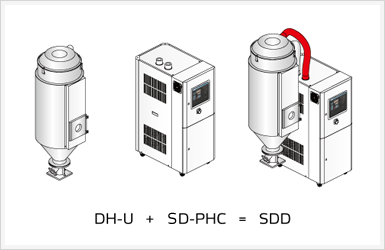

By being flexibly combined with DH-U of different capacities, rotary dehumidifier SD-PHC (with heater and controller) can become dehumidifying dryers which have the same function with SDD to effectively dehumidify and dry absorbent plastic material. Therefore, it’s no need to provide series of SHD-U and SDD, and thus to reduce inventories and operation cost. DH-U can be flexibly equipped according to configuration standard to offer rapid supply of material and operate efficiently.

By being flexibly combined with DH-U of different capacities, rotary dehumidifier SD-PHC (with heater and controller) can become dehumidifying dryers which have the same function with SDD to effectively dehumidify and dry absorbent plastic material. Therefore, it’s no need to provide series of SHD-U and SDD, and thus to reduce inventories and operation cost. DH-U can be flexibly equipped according to configuration standard to offer rapid supply of material and operate efficiently.

Special Reports

- Application of Plastics Auxiliary Equipment

- Solutions of Central Cooling System

- The Application of Honeycomb Dehumidifier

- Temperature Control of Hot Runner System

- System or Individual Setup

If you want to read other articles, back to2013 Quarter 4 Issue 17.