Special Reports

2013 Quarter 4 Issue 17

System or Individual Setup

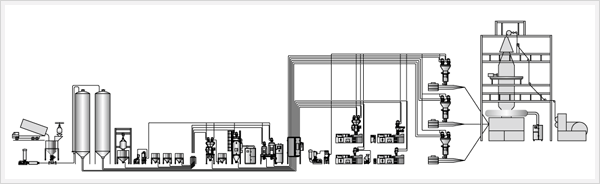

Along with the development of industrial technology and requirement of improving efficiency, material feeding of molding machine tends to be automatic, intelligent and user-friendly. There are two main ways of feeding: system control or individual setup. It’s necessary to consider all kinds of conditions to see what kind of device is the most suitable for production when choosing central feeding system of injection molding machine or conveying of one machine.

First of all, consider production requirements, molding production technology, product structure and process ability.

Secondly, consider device cost, device cover area, energy consumption, stability, maintenance cost and time for repairing. Besides dehumidifier, dryer and conveyor, it involves many other devices during the production of plastics. All manufacturing-type enterprises hope to use devices which are of low cost, high efficiency and stable performance. How to choose the best device? How to tell the difference between centralized conveying of plastic raw material and one machine conveying in plastic molding process?

The great characteristics of system control are efficient, manpower saving, stable. It also features strong expanded function, improved environment of production field, more user friendly touch-operation and auto-management.

Central control station can control feeding of one or more vacuum pumps toward loading machines as well as immediately control external signal, working condition and potential failures. Visualized touch screen style human-machine interface which is easy to operate and powerful greatly improve the degree of system automation and save energy. Central control allows setting different parameters and directly monitor via touch-screen. Individual setup can’t realize to control at the same place and it takes a too long time to start up which make it inefficient.

Central control can realize remote control: one vacuum pump can feed several machines. For example, if there are 10 injection molding machines to feed, it just need one vacuum pump when adopting central control while 10 hopper loaders for individual setup. Individual setup is greater than the one of central control in energy consumption and can’t control at the same place.

The working conditions of system control and individual setup are different. For system control, the working condition around main machine is greatly improved to provide a clean working environment which ensures no contamination of material, because of centralized storage of material, centralized collecting of dust and being away from production site. As for individual setup, it needs more space to put raw material, which may be not in order and thus easy to make mistakes when feeding. Besides, it can not realize centralized collecting of dust. In addition, central feeding system can reduce labor intensity by allowing material feeding without workers and no requirement of labor to carry raw material.

For central feeding of material, materials are also processed in a central way if material requires dehumidifying and drying, which ensures that material is not affected with moisture during conveying and ensures low energy consumption. Material conveying which is in enclosed way can control material quantity. For workshop using air conditioner, central system control will keep the environment temperature stable by not releasing heat to workshop. In individual setup, all dryers can just be put beside the main machine and thus release heat to workshop directly.

Central feeding system can realize to convey different kinds of raw material and sort processed materials according to set types. Besides, it can change raw material fast while the individual setup can’t realize to switch material in that way. For individual setup, it just allows one-to-one feeding but no change.

For individual setup, it’s more flexible to exchange machines and can stop running at any time. When one vacuum pump stops running, other molding machines, like injection molding machine, also will stop feeding. For individual setup, it can make one machine stopped running without having any influence on other machines when cleaning and repairing. However, for system control, it can be equipped with a set of spare vacuum pumps which is available to be used when cleaning and repairing to ensure no machine halt for system. There are more workloads of individual setup than those of system control. Besides, the operating cost of individual setup is higher than the one of system control, since the easy-wear parts in individual setup are more than in system control.

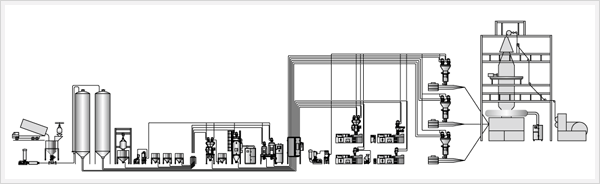

First of all, consider production requirements, molding production technology, product structure and process ability.

Secondly, consider device cost, device cover area, energy consumption, stability, maintenance cost and time for repairing. Besides dehumidifier, dryer and conveyor, it involves many other devices during the production of plastics. All manufacturing-type enterprises hope to use devices which are of low cost, high efficiency and stable performance. How to choose the best device? How to tell the difference between centralized conveying of plastic raw material and one machine conveying in plastic molding process?

The great characteristics of system control are efficient, manpower saving, stable. It also features strong expanded function, improved environment of production field, more user friendly touch-operation and auto-management.

Central control station can control feeding of one or more vacuum pumps toward loading machines as well as immediately control external signal, working condition and potential failures. Visualized touch screen style human-machine interface which is easy to operate and powerful greatly improve the degree of system automation and save energy. Central control allows setting different parameters and directly monitor via touch-screen. Individual setup can’t realize to control at the same place and it takes a too long time to start up which make it inefficient.

Central control can realize remote control: one vacuum pump can feed several machines. For example, if there are 10 injection molding machines to feed, it just need one vacuum pump when adopting central control while 10 hopper loaders for individual setup. Individual setup is greater than the one of central control in energy consumption and can’t control at the same place.

The working conditions of system control and individual setup are different. For system control, the working condition around main machine is greatly improved to provide a clean working environment which ensures no contamination of material, because of centralized storage of material, centralized collecting of dust and being away from production site. As for individual setup, it needs more space to put raw material, which may be not in order and thus easy to make mistakes when feeding. Besides, it can not realize centralized collecting of dust. In addition, central feeding system can reduce labor intensity by allowing material feeding without workers and no requirement of labor to carry raw material.

For central feeding of material, materials are also processed in a central way if material requires dehumidifying and drying, which ensures that material is not affected with moisture during conveying and ensures low energy consumption. Material conveying which is in enclosed way can control material quantity. For workshop using air conditioner, central system control will keep the environment temperature stable by not releasing heat to workshop. In individual setup, all dryers can just be put beside the main machine and thus release heat to workshop directly.

Central feeding system can realize to convey different kinds of raw material and sort processed materials according to set types. Besides, it can change raw material fast while the individual setup can’t realize to switch material in that way. For individual setup, it just allows one-to-one feeding but no change.

For individual setup, it’s more flexible to exchange machines and can stop running at any time. When one vacuum pump stops running, other molding machines, like injection molding machine, also will stop feeding. For individual setup, it can make one machine stopped running without having any influence on other machines when cleaning and repairing. However, for system control, it can be equipped with a set of spare vacuum pumps which is available to be used when cleaning and repairing to ensure no machine halt for system. There are more workloads of individual setup than those of system control. Besides, the operating cost of individual setup is higher than the one of system control, since the easy-wear parts in individual setup are more than in system control.

Special Reports

- Application of Plastics Auxiliary Equipment

- Solutions of Central Cooling System

- The Application of Honeycomb Dehumidifier

- Modular Application of Dehumidifying Dryer

- Temperature Control of Hot Runner System

If you want to read other articles, back to2013 Quarter 4 Issue 17.