Special Reports

2014 Quarter 4 Issue 21

Oil Filter Applied in Plastics Drying and Dehumidifying

In plastics injection molding, some plasticizers will be usually added into plastics to improve plastics molding processing properties. In material drying, hot air through granules surface will dissolve a part of vaporized plasticizers.

But material drying and dehumidifying system is usually a closed-loop circulation. If air returned from the drying hopper contains plasticizers, it will affect the dehumidifying effects of dehumidifiers and other adsorbents.

Therefore, when there are lots of plasticizers included in the return air from drying and dehumidifying system, a return-air oil filter will be installed to filter the oil in the air which passed through the adsorbents.

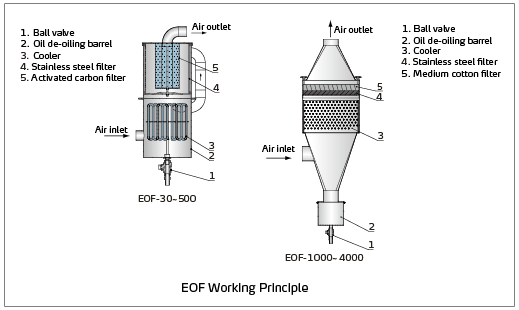

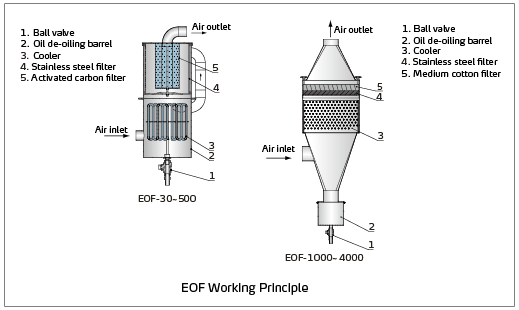

Shini Group developed oil filter EOF which adopts two-stage filtering method. There are 2 models with different structures according to the air flow. They are EOF-30~500 and EOF-1000~4000, their air-flow handling capacity is respectively 30~500m3/hr and 1000-4000m3/hr.

EOF-30~500 model adopts activated carbon filtering method. High-temperature return air containing plasticizers firstly passes through the cooler, then the gaseous plasticizer and a little of vapor condensed liquid oil-water mixture would be excluded. Residual mixing gas firstly passes through the first mesh of the stainless steel filter which has 200 meshes, the majority of the oil granules will be excluded. Then through the activated carbon filter, it filters the subtle granules in the air. Therefore, the oil granules of plasticizer in return air are drawn out.

EOF-30~500 model adopts activated carbon filtering method. High-temperature return air containing plasticizers firstly passes through the cooler, then the gaseous plasticizer and a little of vapor condensed liquid oil-water mixture would be excluded. Residual mixing gas firstly passes through the first mesh of the stainless steel filter which has 200 meshes, the majority of the oil granules will be excluded. Then through the activated carbon filter, it filters the subtle granules in the air. Therefore, the oil granules of plasticizer in return air are drawn out.

EOF-1000~4000 adopts middle-effect cotton filtering method. In the same way, the high-temperature return air with plasticizer firstly passes through high-efficiency fin style cooler to make easier liquidation of the gaseous grease as well as to exclude the gaseous plasticizer and a little of vapor condensed liquid oil-water mixture. Residual mixing gas firstly passes through the first mesh of the stainless steel filter which has 200 meshes, filter out the majority of the oil granules. Then through middle-effect cotton filter, it filters the subtle granules in the air. Therefore, the oil granules of plasticizer in return air are drawn out.

Drying and dehumidifying system of material containing plasticizer adopts this oil filter which ensures stable dehumidifying property. It extends the service life of the dehumidifiers and lowers the production cost. It’s really cost-effective.

But material drying and dehumidifying system is usually a closed-loop circulation. If air returned from the drying hopper contains plasticizers, it will affect the dehumidifying effects of dehumidifiers and other adsorbents.

Therefore, when there are lots of plasticizers included in the return air from drying and dehumidifying system, a return-air oil filter will be installed to filter the oil in the air which passed through the adsorbents.

Shini Group developed oil filter EOF which adopts two-stage filtering method. There are 2 models with different structures according to the air flow. They are EOF-30~500 and EOF-1000~4000, their air-flow handling capacity is respectively 30~500m3/hr and 1000-4000m3/hr.

EOF-1000~4000 adopts middle-effect cotton filtering method. In the same way, the high-temperature return air with plasticizer firstly passes through high-efficiency fin style cooler to make easier liquidation of the gaseous grease as well as to exclude the gaseous plasticizer and a little of vapor condensed liquid oil-water mixture. Residual mixing gas firstly passes through the first mesh of the stainless steel filter which has 200 meshes, filter out the majority of the oil granules. Then through middle-effect cotton filter, it filters the subtle granules in the air. Therefore, the oil granules of plasticizer in return air are drawn out.

Special Reports

- Shini Gravimetric Blender SGB Flakes Solution

- Gravimetric Blender SGB Data-collection Software

- Shini Granulator Energy-saving Motor Update

- Application of SLWF in Extrusion Molding Machine

- Shini Launches Energy-saving Hopper Dryer SHD-EH

- Modular Drying and Dehumidifying

If you want to read other articles, back to2014 Quarter 4 Issue 21.