Blow molding process consists of two main molding methods: extrusion blow molding and injection blow moulding. Through extrusion or injection molding, thermoplastic resin is molded into tube-shaped parison which are instantly (when it is still hot or heat it up to the state of softening) put into blowing mold. Then compressed air is blown into it until it expanded and sticked on mould cavity. After cooling and demolding, hollow products can be finished.

Blow molding technic is used in the production of hollow thin-walled parts with for thermoplastic materials. The typical products of blow molding are large capacity and the final consumer goods, such as bottles and containers. At present, the most popular materials for blow molding are PE, PP and PVC.

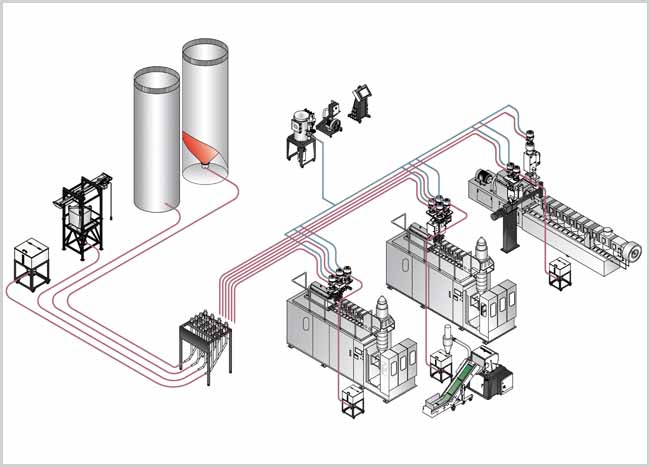

Central or single unit control method can be chosen according to the number and positions of the blow molding machines in the workshop.

All material contact surfaces are made of stainless steel, together with filtering device in the conveying system, no contamination can be assured.

Auto loader has vacuum pump which can maintain high efficiency, also filter device, time difference real-time detection device or vacuum-protecting device is equipped to timely clean and protect the vacuum pump.

Material consumption of extrusion molding is large, the selections of air quantity and the pipe diameter become very important, for not only the material consumption for each molding machine, also the long distance conveying should be taken into consideration.

Central or single unit control method can be chosen according to the number and positions of the blow molding machines in the workshop.

All material contact surfaces are made of stainless steel, together with filtering device in the conveying system, no contamination can be assured.

Auto loader has vacuum pump which can maintain high efficiency, also filter device, time difference real-time detection device or vacuum-protecting device is equipped to timely clean and protect the vacuum pump.

Material consumption of extrusion molding is large, the selections of air quantity and the pipe diameter become very important, for not only the material consumption for each molding machine, also the long distance conveying should be taken into consideration.

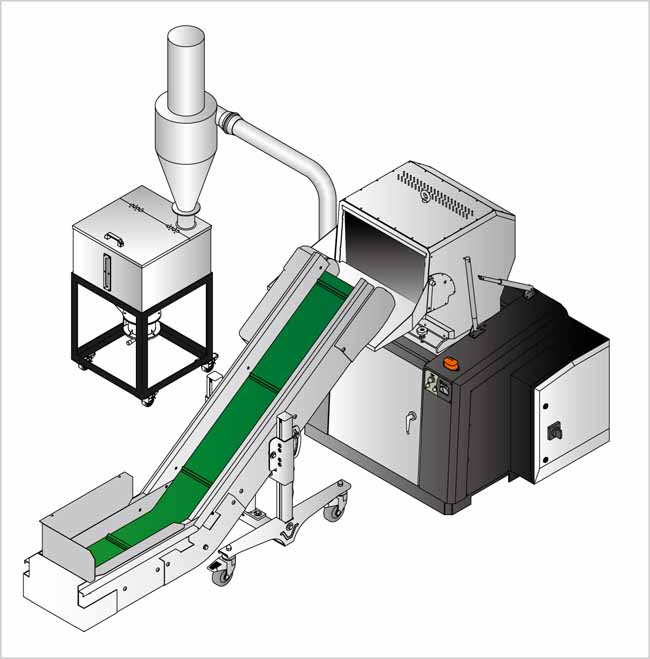

Granulating

Shini granulators are applicable to granulating of all kinds of recycled plastic products such as pre-forms and PET bottles. Centralized control design makes operation easier; openable cutting chamber makes cleaning easier; multi-safety device ensures no damage to machine and operator.

Dosing & Mixing

Volumetric Doser SCM

SCM model of Shini is suitable for masterbatch particles both crystallized and non-crystalline with output within 0.2~32

kg/hr. If the masterbatch proportion and precision is demanding, SGD model is suggested which adopt loss-in-weight calculation with output within 0.04~32kg/hr.

Gravimetric Blender SGB

In extrusion molding, main strain, masterbatch and regrinds are proportional mixed in gravimetric blender SGB. The output of Shini SGB is with 40~3,000kg/hr with 2~8 ingredients.

Ethernet interface attached to the controller works together with the relevant software, material proportion data can be transmitted to control product quality. Also, central monitoring can be realized through this interface (based on the MODBUS-TCP/IP protocol).

Loss-in-weight Feeder SLWF

Loss-in-weight feeder adopt hungry feeding technology, by detecting actual material flow, the screw speed of the feeder can be automatically adjusted to achieve and maintain set flow amount. Hermetic design avoids ambient condition influence. Also, no material splashing will occur during power material feeding.

Loss-in-weight Hopper Syline

SYline is a gravimetric loss-in-weight hopper designed to gravimetrically feed the extruder throat controlling the throughput set. The weight of hopper and relevant material is weighted by two off-centre load cell. Based on commercial modular PLC electronics, SYline ensures simple and practical operation. Control software of SYline are loss-in-weight control, gram/meter and throughput control, material consumption control.

Gain-in-weight Batch Blender eaSYbatch

eaSYbatch is the traditional gain-in-weight batch blender, designed to dose and blend multiple components. Using modularized PLC technology, the simple and practical operation can be assured. Control software of eaSYbatch consists of loss-in-weight control, gram/meter and throughput control, material consumption control.

Loss-in-weight continuous Dosing System SYdos

SYdos is continuous loss-in-weight gravimetric dosing system designed to dose and feed multiple components in all process in which a constant gravimetric feeding is required. Main material is weighed by two off-centre load cells and the data is transfer to control system to adjust the screw speed with the data transferred by each load cells of other materials. Control software of SYdos consists of loss-in-weight control, gram/meter and throughput control and material consumption control.

SCM model of Shini is suitable for masterbatch particles both crystallized and non-crystalline with output within 0.2~32

kg/hr. If the masterbatch proportion and precision is demanding, SGD model is suggested which adopt loss-in-weight calculation with output within 0.04~32kg/hr.

Gravimetric Blender SGB

In extrusion molding, main strain, masterbatch and regrinds are proportional mixed in gravimetric blender SGB. The output of Shini SGB is with 40~3,000kg/hr with 2~8 ingredients.

Ethernet interface attached to the controller works together with the relevant software, material proportion data can be transmitted to control product quality. Also, central monitoring can be realized through this interface (based on the MODBUS-TCP/IP protocol).

Loss-in-weight Feeder SLWF

Loss-in-weight feeder adopt hungry feeding technology, by detecting actual material flow, the screw speed of the feeder can be automatically adjusted to achieve and maintain set flow amount. Hermetic design avoids ambient condition influence. Also, no material splashing will occur during power material feeding.

Loss-in-weight Hopper Syline

SYline is a gravimetric loss-in-weight hopper designed to gravimetrically feed the extruder throat controlling the throughput set. The weight of hopper and relevant material is weighted by two off-centre load cell. Based on commercial modular PLC electronics, SYline ensures simple and practical operation. Control software of SYline are loss-in-weight control, gram/meter and throughput control, material consumption control.

Gain-in-weight Batch Blender eaSYbatch

eaSYbatch is the traditional gain-in-weight batch blender, designed to dose and blend multiple components. Using modularized PLC technology, the simple and practical operation can be assured. Control software of eaSYbatch consists of loss-in-weight control, gram/meter and throughput control, material consumption control.

Loss-in-weight continuous Dosing System SYdos

SYdos is continuous loss-in-weight gravimetric dosing system designed to dose and feed multiple components in all process in which a constant gravimetric feeding is required. Main material is weighed by two off-centre load cells and the data is transfer to control system to adjust the screw speed with the data transferred by each load cells of other materials. Control software of SYdos consists of loss-in-weight control, gram/meter and throughput control and material consumption control.