Special Reports

Intelligent Flow Regulator SIFR

Features

1.Digital flow and temperature monitoring system is able to process real-time control of the flowrate, temperature in each pipe, which can display instant mould loop blockage to avoid the rejects.

2.The regulating value in each return loop can control precise flowrate in each loop by adjusting different water loops.

3.7” touch panel presents clear display of simple operations.

4.The display of graphic and numerical data enables more intuitive adjustment of the return loop.

5.Alarms for real-time flowrate and temperature monitoring indicate abnormalities in the loop in time.

6.RS485 communication interfaces make centralized monitoring with the host units available.

Options

3/8” quick hose coupler,quick pipe connector,Teflon tube connector, Floor mount are optional.

Application

SIFR series intelligent flow regulator is designed to work with water heater, water chiller or cooling tower that can connect with multiple mould interfaces. Its functions of temperature, flowrate monitoring and control can adapt to different working conditions.

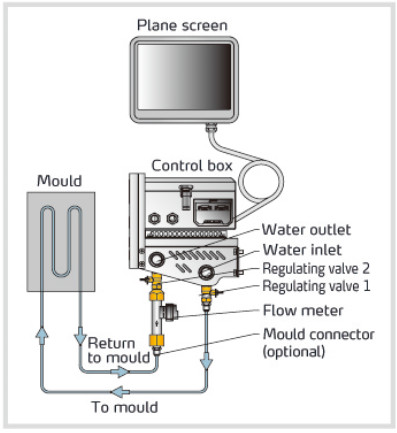

Working Principle

Circulating water enters the flow regulator through the water inlet.

Circulating water enters the mould via the regulating valve 1.

When circulating in mould, the water enters the flow monitor via the valve 2 of the regulator, and the water flowrate and temperature data are monitored by the electronic flow meter.

The circulating water then returns to the water heater, water chiller or cooling tower through water outlet.

The data detected by the flow meter will be connected to the panel screen in display.

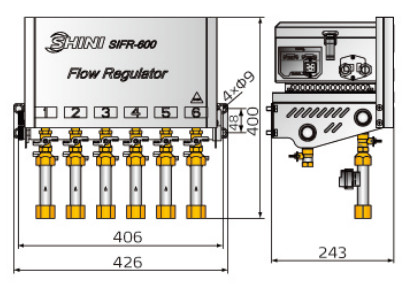

Outline Drawings

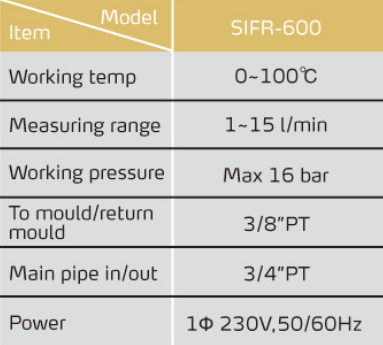

Specifications

Special Reports

- Hastek Brief Company Introduction

- CFC-free Refrigerant Water-cooled Water Chiller SIC-17W-R2

- High Temp. Oil Heater STM-1207HT

- Screenless Granulator SG-2427N

- Small Articulating Robot

- Multi-cavity Hot Runner Controller

- Application Case of Hot Runner Multi-head Nozzle with PC Materials

If you want to read other articles, back to2018 Quarter 3 Issue 36.