Special Reports

High Temp. Oil Heater STM-1207HT

Features

1.Controller adopts 3.2 " LCD for easy operation.

2.Equipped with the design of 7-day automatic start/stop timer. LCD screen can be converted between Chinese and English. The unit of temperature can be converted between oF and ℃.

3.P.I.D. multi-stage temperature control system can maintain stable mould temperature with an accuracy of ±0.5℃.

4.Adopts high efficiency high temperature pump, which can meet the demands of temperature control for precise moulds and mould loop with minor diameter to achieve precise temperature control and high efficient heat exchange.

5.Multiple safety devices include power reverse phase protection, pump overload protection, overheat protection and low level protection that can automatically detect abnormal performance and indicate this via visible alarm.

6.Pipe heaters are made of stainless steel.

7.Temp. control range of 40~350℃ that is applicable to die casting, roller and other high-temp. occasions.

8.The heating control adopts SSR solid state relay ensuring fast output control frequency, high temp. control accuracy and long service life.

9.The cooling control adopts indirect sleeve cooling structure and the cooler without contacting the hot oil for longer service life.

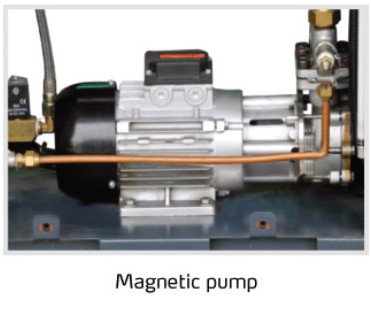

10.Equipped with magnetic pump and its internal structure is made of high pressure resistance stainless steel to prevent any explosion.

11.Equipped with RS485 communication interface to realize centralized monitoring.

12.The buzzer is equipped.

Options

1.Water manifolds, Teflon hose and Transfer oil are optional.

2.Displays of mold temperature and return oil temperature of mold are optional.

3.It could option with magnetic filter to prolong service life of magnetic pump (only suitable for models with magnetic pump). Add “MF” at the end of the model code.

4.Built-in cooler is optional to increase the cooling capacity.

Application

This model of machine is used for mould heating and maintaining constant temp., which is also applicable for die casting, roller and other high-temp. industries occasions.

Special Reports

- Intelligent Flow Regulator SIFR

- Hastek Brief Company Introduction

- CFC-free Refrigerant Water-cooled Water Chiller SIC-17W-R2

- Screenless Granulator SG-2427N

- Small Articulating Robot

- Multi-cavity Hot Runner Controller

- Application Case of Hot Runner Multi-head Nozzle with PC Materials

If you want to read other articles, back to2018 Quarter 3 Issue 36.