About Our Technology Management

& Manufacturing

Shini Group introduced both advanced science and technology management concepts.

Technology Management

Shini Group introduced both advanced science and technology management concepts which consist of re-design of corporate information system, ERP project, self-developed eLearning system, knowledge management system, transformation of R&D process, re-built of quality control system, introduction of customer training system, product resume design and customer service management system.

These reforms will help Shini transfer from production-oriented to technology-oriented, from manufacture to service innovation, from local company to international enterprise.

Implementation of ERP System

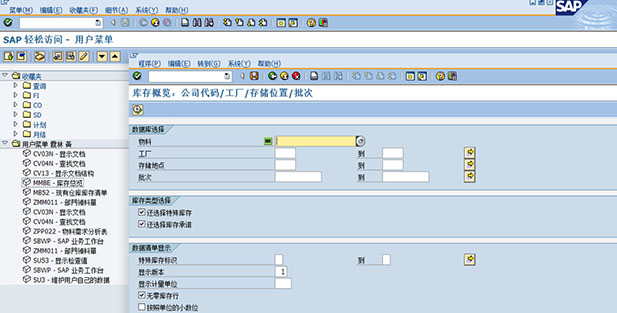

When a small business company extends to a group of a business corporations, we need a management information system to integrate the internal resources and instantly reflect each plant's performance. The vision of implementing the ERP system has been backdated to December 2008. With joint efforts of all members, the ERP system was incorporated into Taiwan and Dongguan facilities on New Year's Day of 2010 and Pinghu Plant on February 1st in, 2010.

Learning System

After more than two years of effort, we have successfully developed the eLearning System and introduced a customer training mechanism. We have designed course syllabi, curriculum content, materials, and recorded training courses according to the standard of product training courses. There are now a total of more than 400 courses which consist of the company profile, product training, production management, internal administration, and information courses. We will also share the training material (Chinese and English Versions) with domestic and overseas reps.

Knowledge Management

Established over 50 years, Shini Group has accumulated rich experience in the plastics industry and introduced a knowledge management system to organize, publish and share valuable expertise about R&D, quality management, production management, customer service, customer/employee training, product application, marketing, business promotion, exhibition management, and human resources management.

Manufacturing

Technologies and talents are the keys to advancement.

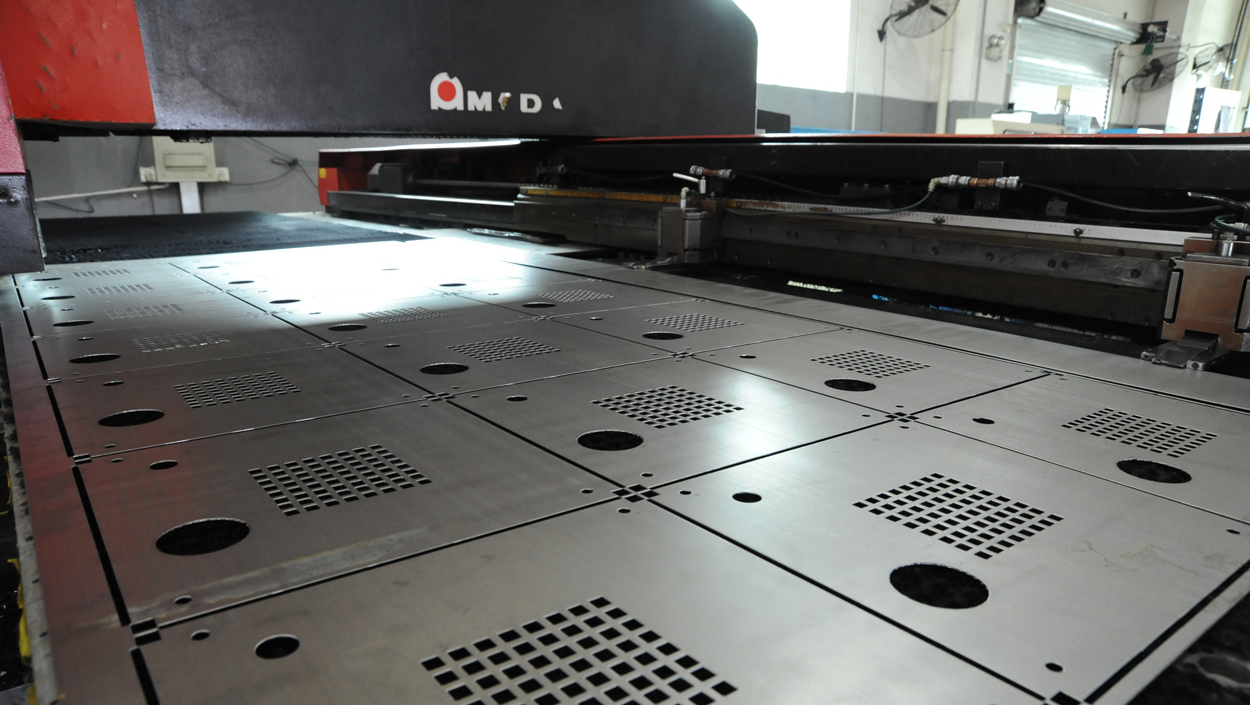

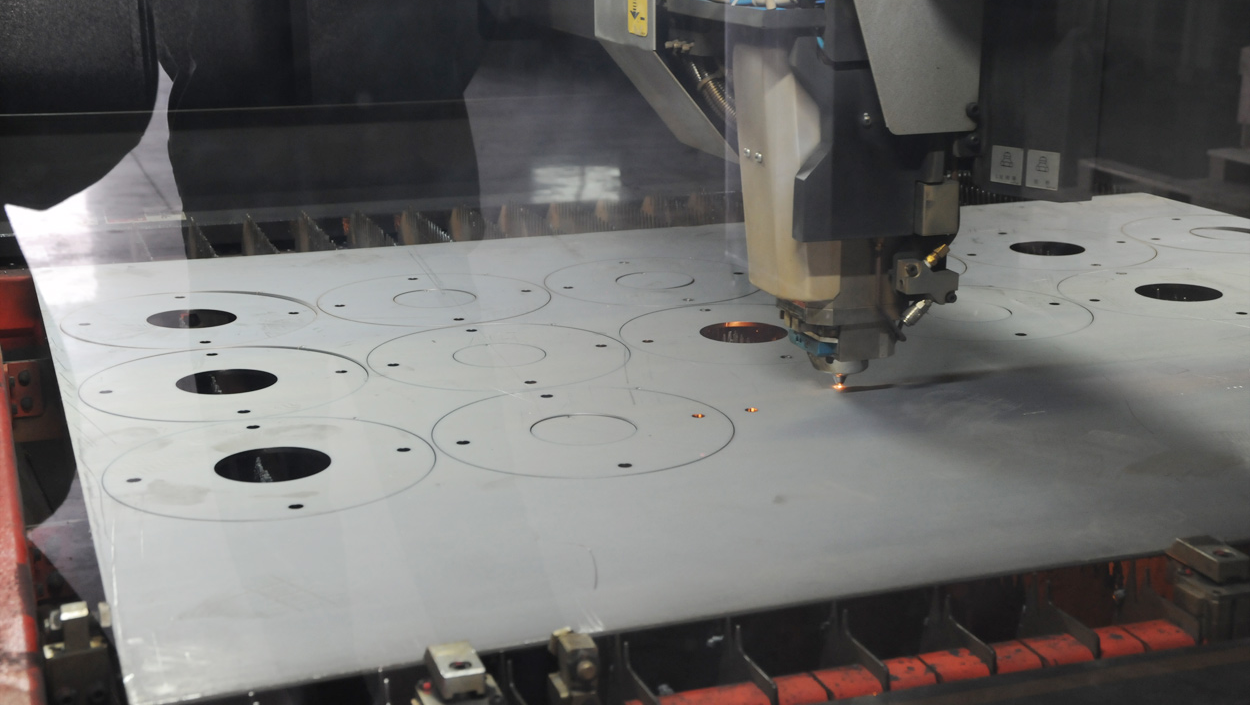

Lean production and integrated manufacturing are major features of Shini. We utilize well-known global CNC punching, shearing, hydraulic pressing, laser cutting, CNC turning, milling, and automated powder coating systems for precise machining. The lean production technologies and advanced equipment, we achieved over 70% self-produced rate.

Shini plastics material handling equipment is well-recognized and reliable in the local and global markets. And is practical in energy saving and enhancing production efficiency.

BYD and TOYOTA in car manufacturing, FOXCONN in electronics manufacturing, SANYO, SIEMENS, and HAIER in home appliances manufacturing, HSUFUCHI in food production, JIN-JIAN in Medical Industry, and several well-known companies all utilize Shini plastics material handling equipment. The recognition from these business organizations all reflects Shini 's values and quality.

Technologies and talents are the keys to advancement.

Shini focuses on innovation integration, process optimization, modern management system, and global human resources to build up a team of elites with an international perspective. Moreover, Shini also focuses on strategic cooperation with colleges to educate potential future leaders.