STM-W series mould temperature controllers work with water as a heat transfer medium, which heats the mould and maintains its temperature for just the right injection process without the annoyance of cleaning the heat transfer oil, which ensures clean production for demanding production or standards. STM-W furthermore features simple but efficient direct water cooling, which can be used in other similar applications. The close loop and pressurized water circulate in the hermetic pipes, and the water remains in a liquid state even if the temperature is higher than 100°C, which provides the need for higher working temperature requirements. Nevertheless, it has many options for a much more technical production process and requirements, such as digital flow sensors, magnetic-driven pumps, filters, additional thermocouples, and more.

Features

- For standard STM-W, the maximum heating temperature reach up to 120℃/248℉.

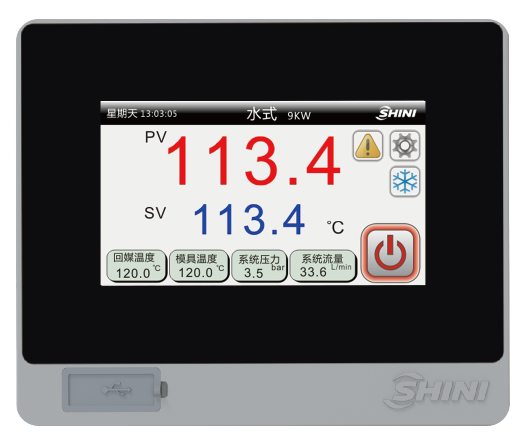

- P.I.D controller with 4.3" LCD with an intuitive and user-friendly interface;

- Standard equipped with flow display function;

- In build weekly timer with ℃/℉ unit conversion.

- STM-607W/910W adopts non-contact heater to reduce the water quality impact on the pipe heater and prolong the heater’s service life.

- The multi-stage P.I.D. controller can maintain stable mould temperature with a precision of +/- 0.5℃/0.9℉.

- SSR solid-state relay

- Adopt a high-efficiency water pump.

- Multiple built-in safety displayers and alarm devices, such as phase reverse protector, pump overload protector, and overheat protectors.

- Equipped with high/low pressure protection, auto water supplying and air exhausting functions.

- Direct cooling with excellent refrigerating effect. Auto refilling device cools down the temperature to set value directly.

- Modbus RTU data communication via RS485 for centralized control

- Standard buzzer