Simple and Automated Bulk Bag Unloading System : Ease Your Plastic Material Handling Process

Handling large quantities of plastic materials can be challenging and time-consuming, especially involving manual labor. It's essential to have an efficient system in place to ensure that the material handling process is streamlined, secure, and cost-effective. This is where the bulk bag unloading equipment comes in. In this article, we will look at how a bulk bag unloading system can help ease your plastic material handling process and make it more automated.

What is a Bulk Bag Unloader?

Bulk bag unloaders, also referred to as bulk bag dispensers or super sack unloaders, are expertly crafted to efficiently convey the plastic material from flexible intermediate bulk containers (FIBCs) or super sacks into industrial plastic material processes. These automated unloading systems are ideal for efficiently handling all plastic pellets or materials without requiring manual intervention.

These systems are designed to accommodate a range of bulk bags and containers, including Octabins, Gaylord Boxes, Super Sacks, and bags with plastic liners. They offer a low-maintenance solution for material handling and eliminate the need for manual lifting, tilting, or turning of bags.

The bulk bags can be easily transported to the discharging or uploading station with a pallet truck. The conveying process can be initiated automatically, resulting in smooth plastic material handling without interruption. The automated bulk bag unloading system is engineered to empty the bulk bags, leaving no residual material.

How Does it Work to Ease Your Material Handling ?

An automated bulk bag unloader is a device that efficiently removes plastic material from large bulk bags. The following steps outline the process by which this system operates:

-

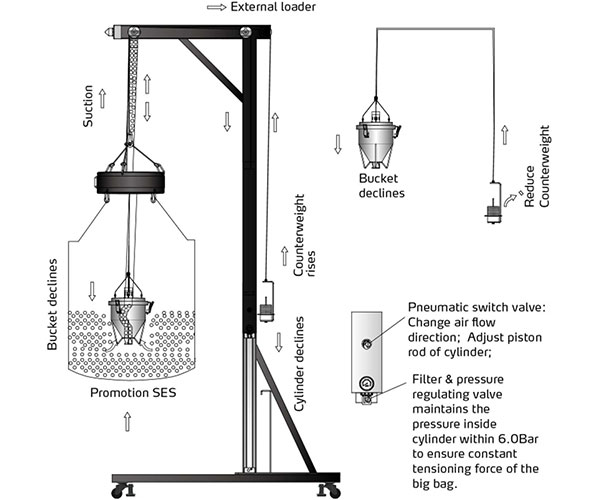

1. Start the pneumatic reversing valve to raise the cylinder.

-

2. The lifting device will descend to secure the bulk bag or container bag at the desired height.

-

3. Once the bulk bag or container bag is securely in place, activate the pneumatic reversing valve to lower the cylinder.

-

4. The lifting device will then tighten the bulk bag or container bag to ensure stability during the conveying process.

-

5. Reduce the balancing weight to cause the loader to descend into the bulk bag or container bag for material suction.

-

6. As the material is being empty, the weight of the bulk bag or container bag will gradually decrease until it is less than the tightening force.

-

7. The entire bulk bag or container bag will then be lifted and concentrated the material, allowing for the suction of the remaining material.

-

8. When the cylinder reaches its limit and triggers the sensor, the alarm light will turn on to signal the completion of the conveying process.

The automated bulk bag unloader operates through a combination of pneumatic control, lifting devices, and load balancing to efficiently and safely remove material from large bulk bags or container bags.

2 Core Technologies of Simple and Automated Bulk Bag Unloading Equipment

Bulk bag unloaders are essential to many plastic material handling processes for injection moulding, extrusion, blow moulding, or recycling industries. There are two key technologies that drive the efficient and effective operation of these devices and equipment :

-

1. Loading Unit:

This technology includes an anti-block handrail on the loading bag, which prevents material from clogging the inlet and disrupting the conveying process. An optional vibration module is also placed above the loading device to ease the operation of poor-flowing material.

-

2. Lifting Devices:

These devices securely hold the bag and prevent tilt or material leakage. As the material is sucked, the lifting device will raise the bag as the material decreases until it reaches the limit, ultimately lifting the bag empty.

The combination of these two core technologies makes bulk bag unloaders an indispensable part of many plastic material handling systems. They ensure efficient and effective material removal without disruption or material loss.

In conclusion, the automated bulk bag unloader is a highly versatile solution that offers a range of benefits for efficient and effective plastic material handling. These systems are designed to accommodate a range of bulk bags and containers, making them an ideal solution for the efficient handling of all plastic pellets or materials.

After Shini successfully launched the Auto Loader for Big Bags, it has been favored by vast users on markets and received continuous orders, great field application effect and high praises. To learn more about the automated bulk bag unloader and how it can help ease your plastic material handling process, please visit Auto Loader or Contact Us today !