Single-unit Application

SMM is installed at the bottom of the hopper receiver or the autoloader. It enables real-time monitoring of material consumption. The operator can record the product qualification rate to adjust the equipment according to material consumption data and the qualified product quantity. SMM also can supply drying materials on demand to reduce the conventional drying and exchanging time. It improves productivity.

Application of Central Conveying

When used in plastic production, SMM can upload the weighing data to the main control of central conveying via the communication port. The main control monitors the material consumption of each unit in real-time and makes adjustments. To arrange production reasonably and reduce material waste.

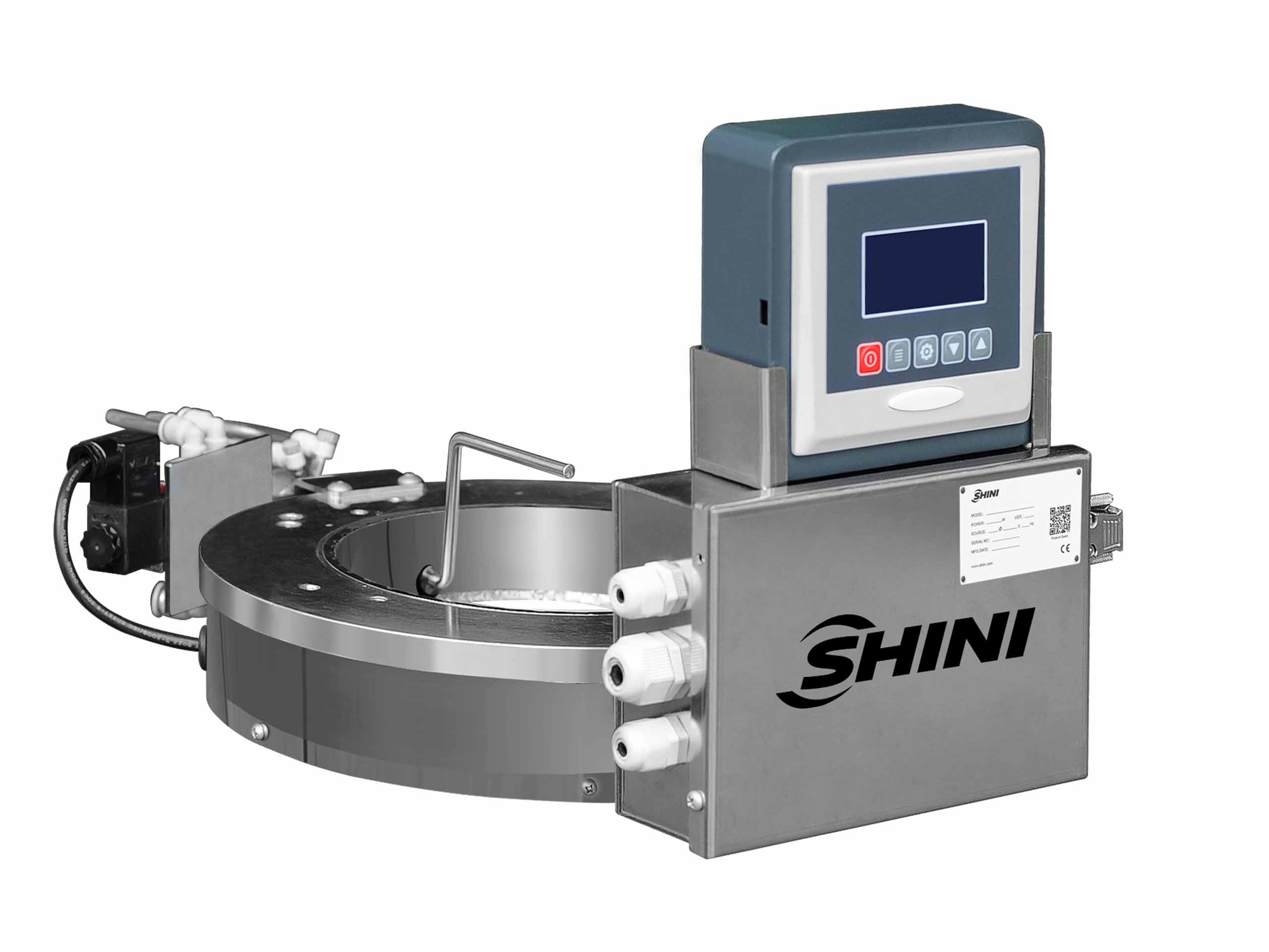

Features

- Real-time material consumption monitoring.

- Production batch control.

- Statistical Material throughput.

- Precision up to ±1%

- The parts in contact with materials are made of stainless steel to ensure no material contamination.

- Standard communication function via RS485