Special Reports

2022 Quarter 1 Issue 46

Why does the granulator use the dust-separating system?

For the restrictions of using plastic materials and requirements of environmental protection worldwide, sustainable development model has gradually become the mainstream economic model.

Granulator with dust-separating system DS

Granulator with dust-separating system DS

Shini has developed and manufactured different types of granulating and recycling equipment to meet users' diversified demands of properties in plastics recycling processes. Most of this equipment is named after SG. It is mainly used for crushing various plastic materials, including granulating, recycling, and reusing the wastes after injection molding, blow molding, or extrusion processes.

Currently, the main products of the SG series include the Low-speed Granulator SG-16N/SG-20N series, the Screenless Granulator SG-14/SG-24N/SG-24T/SG-24EB series, The Sound-proof Central Granulator SG-23/SG-30/SG-36/SG-43/SG-50/SG-70 series, Roll-feed Granulator SGF-26 series, etc. Among them, the Low-speed Granulator SG-16N/SG-20N series and Screenless Granulator SG-14/SG-24N/SG-24T/SG-24EB series can be placed next to the injection molding machine for instant recycling and reuse of the sprues or a small number of granules after the injection molding. They are easy to operate and use and are the necessary equipment in the injection molding industry, working with the robots or removing them.

The Sound-proof Central Granulator SG-23/SG-30/SG-36/SG-43/SG-50/SG-70 series can be placed in a separate cutting room for centralized granulating of waste materials, which have many models and wide application ranges to meet different cutting requirements of the customers.

The Roll-feed Granulator SGF-26 series can crush and reuse all kinds of plastic left overs and scraps.

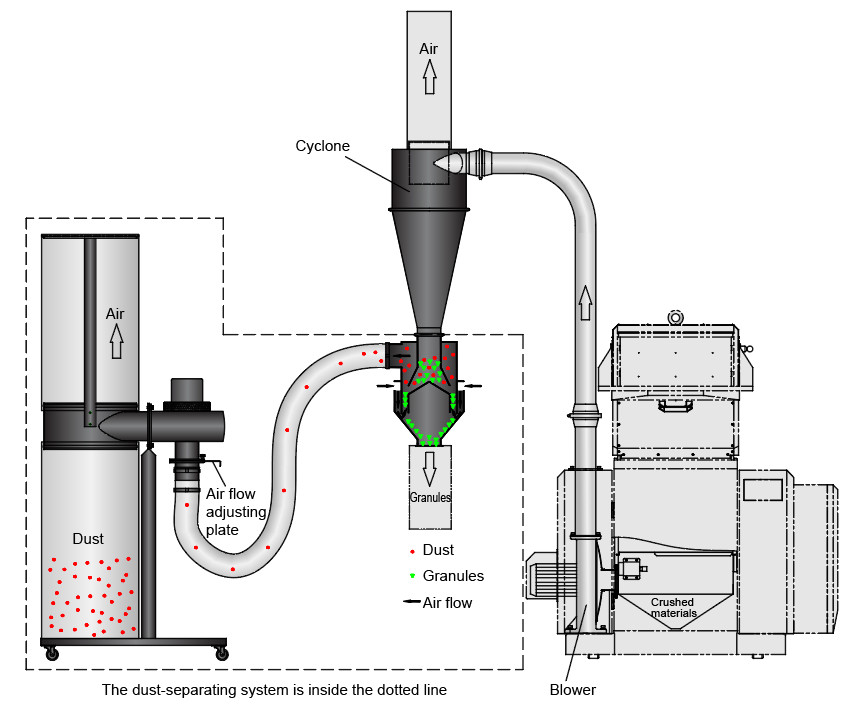

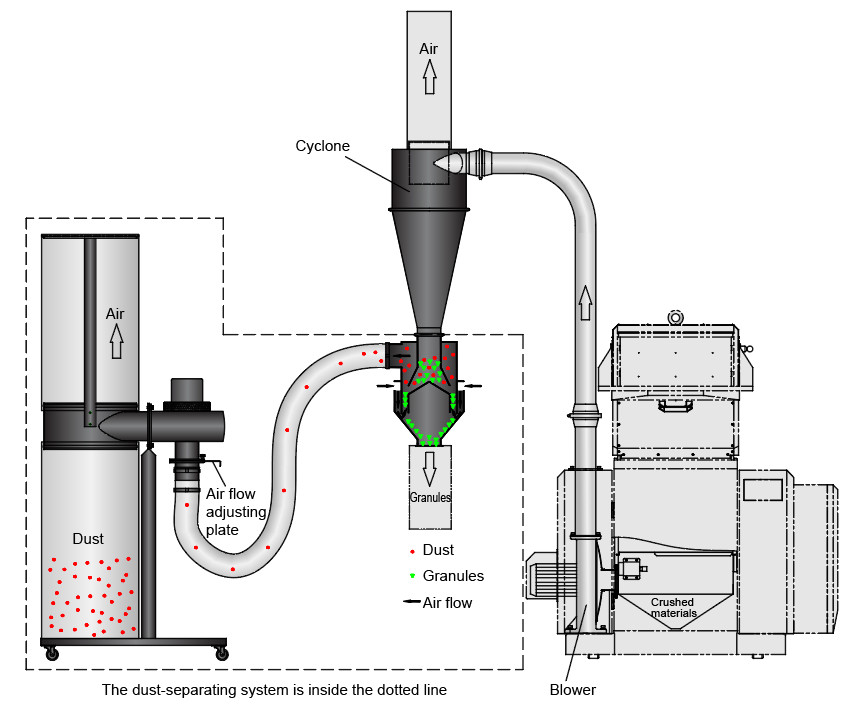

The SG series granulators will inevitably produce dust during the processing, resulting in large dust in the workshop, affecting human health and polluting the environment. Therefore, selecting another dust separating system DS for granulator in the model selection can effectively separate most of the dust in the granules. Collecting the dust in the cloth bag can significantly reduce the pollution to the workshop's environment and solve the problem of excessive dust.

The dust-separating system is equipped with a dust-removing blower and collective cloth bag. After the granules are sent to the cyclone dust collector by the conveying blower, the granules are dropped into the hopper of the dust separator. Then, the materials are dispersed around through the cone hopper, the dust is driven upward by the dust-removing blower and stored in the collective cloth bag, and the particles are dropped directly from the hopper of the dust separator.

Granulator with dust-separating system DS

Granulator with dust-separating system DS

Shini has developed and manufactured different types of granulating and recycling equipment to meet users' diversified demands of properties in plastics recycling processes. Most of this equipment is named after SG. It is mainly used for crushing various plastic materials, including granulating, recycling, and reusing the wastes after injection molding, blow molding, or extrusion processes.

Currently, the main products of the SG series include the Low-speed Granulator SG-16N/SG-20N series, the Screenless Granulator SG-14/SG-24N/SG-24T/SG-24EB series, The Sound-proof Central Granulator SG-23/SG-30/SG-36/SG-43/SG-50/SG-70 series, Roll-feed Granulator SGF-26 series, etc. Among them, the Low-speed Granulator SG-16N/SG-20N series and Screenless Granulator SG-14/SG-24N/SG-24T/SG-24EB series can be placed next to the injection molding machine for instant recycling and reuse of the sprues or a small number of granules after the injection molding. They are easy to operate and use and are the necessary equipment in the injection molding industry, working with the robots or removing them.

The Sound-proof Central Granulator SG-23/SG-30/SG-36/SG-43/SG-50/SG-70 series can be placed in a separate cutting room for centralized granulating of waste materials, which have many models and wide application ranges to meet different cutting requirements of the customers.

The Roll-feed Granulator SGF-26 series can crush and reuse all kinds of plastic left overs and scraps.

The SG series granulators will inevitably produce dust during the processing, resulting in large dust in the workshop, affecting human health and polluting the environment. Therefore, selecting another dust separating system DS for granulator in the model selection can effectively separate most of the dust in the granules. Collecting the dust in the cloth bag can significantly reduce the pollution to the workshop's environment and solve the problem of excessive dust.

The dust-separating system is equipped with a dust-removing blower and collective cloth bag. After the granules are sent to the cyclone dust collector by the conveying blower, the granules are dropped into the hopper of the dust separator. Then, the materials are dispersed around through the cone hopper, the dust is driven upward by the dust-removing blower and stored in the collective cloth bag, and the particles are dropped directly from the hopper of the dust separator.

DS Dust Separator Diagram

When cleaning, it only needs to blow the compressed air around the air supplement vent and discharge port to clean the separating hopper, saving time and energy in the maintenance.

Equipped with the airflow adjusting plate, it can flexibly adjust the dust-removing blower air quantity according to the demands. It is suitable for separating dust in plastic materials with different bulk densities and has manyapplications.

Equipped with the airflow adjusting plate, it can flexibly adjust the dust-removing blower air quantity according to the demands. It is suitable for separating dust in plastic materials with different bulk densities and has manyapplications.

Special Reports

- Advantages of the Air-cooled Drying & Dehumidifying Equipment

- SGB Applied in the Dosing and Mixing of Long Glass-fiber Materials

- Pretreatment of PLA, an Eco-friendly Plastic Material

- The Application of Shut-off Suction Box

- How to choose the right micro-feeder

- Different Applications of Single-shaft Shredder and Large Granulator

- ShiniEurope

- The Origin of the SCC Cooling Consumption Monitor

If you want to read other articles, back to2022 Quarter 1 Issue 46.