Special Reports

2022 Quarter 1 Issue 46

Pretreatment of PLA, an Eco-friendly Plastic Material

Polylactic acid (PLA) is a biodegradable material, and it is made of starch materials extracted from renewable plant resources (such as corn). After use, it can be completely degraded by natural microorganisms, finally generating carbon dioxide and water without environmental pollution. The material is recognized as the eco-friendly material that various standard productions can process, such as melt extrusion molding, injection molding, film blowing molding, foam molding, vacuum forming, etc., with molding conditions similar to those of widely used polymers. Therefore, PLA can meet the demands of different processes to make various products commonly used in food packaging, medical and other fields.

PLA is a strong hygroscopic crystallized material, and the molding process is particularly sensitive to the moisture content and processing temperature. Generally, it needs to ensure the material's dryness drops below 200PPM before it gets into the injection molding machine for processing to meet the demands of the molding process. For plastic materials and molding processes of different properties, Shini provides the Crystallizer, Hot Air Dryer SHD, and Dehumidifying Dryer SCD to the market to meet the demands of various plastic molding processes. Shini can offer a complete set of integrated solutions for crystallizing, dehumidifying, drying, and conveying PLA materials. The dew-point temperature of dry air goes as low as - 40 ℃, wide range temperature set point and accurate airflow control that can fully meet the needs of PLA's pre-drying treatment before the injection molding.

In addition, the Smart Modular Dehumidifying Dryer developed by Shini can always ensure that the plastic materials are in a suitable dry environment and the plastics' dryness reaches an appropriate state. The machine has a recipe function that can store all kinds of recipes according to different materials, which is very friendly to the user's parameter call. The full-touch operation can visually display various information such as drying temp., drying airflow, dew point temperature, and equipment status, and it is very convenient for the operator to use in handy.

The drying airflow of the Shini Dehumidifying Dryer can reach up to 4000m3/hr, and the max drying hopper's capacity of 8000L. That can meet the requirements of mass material processing and customize various specific functions according to actual demands.

PLA is a strong hygroscopic crystallized material, and the molding process is particularly sensitive to the moisture content and processing temperature. Generally, it needs to ensure the material's dryness drops below 200PPM before it gets into the injection molding machine for processing to meet the demands of the molding process. For plastic materials and molding processes of different properties, Shini provides the Crystallizer, Hot Air Dryer SHD, and Dehumidifying Dryer SCD to the market to meet the demands of various plastic molding processes. Shini can offer a complete set of integrated solutions for crystallizing, dehumidifying, drying, and conveying PLA materials. The dew-point temperature of dry air goes as low as - 40 ℃, wide range temperature set point and accurate airflow control that can fully meet the needs of PLA's pre-drying treatment before the injection molding.

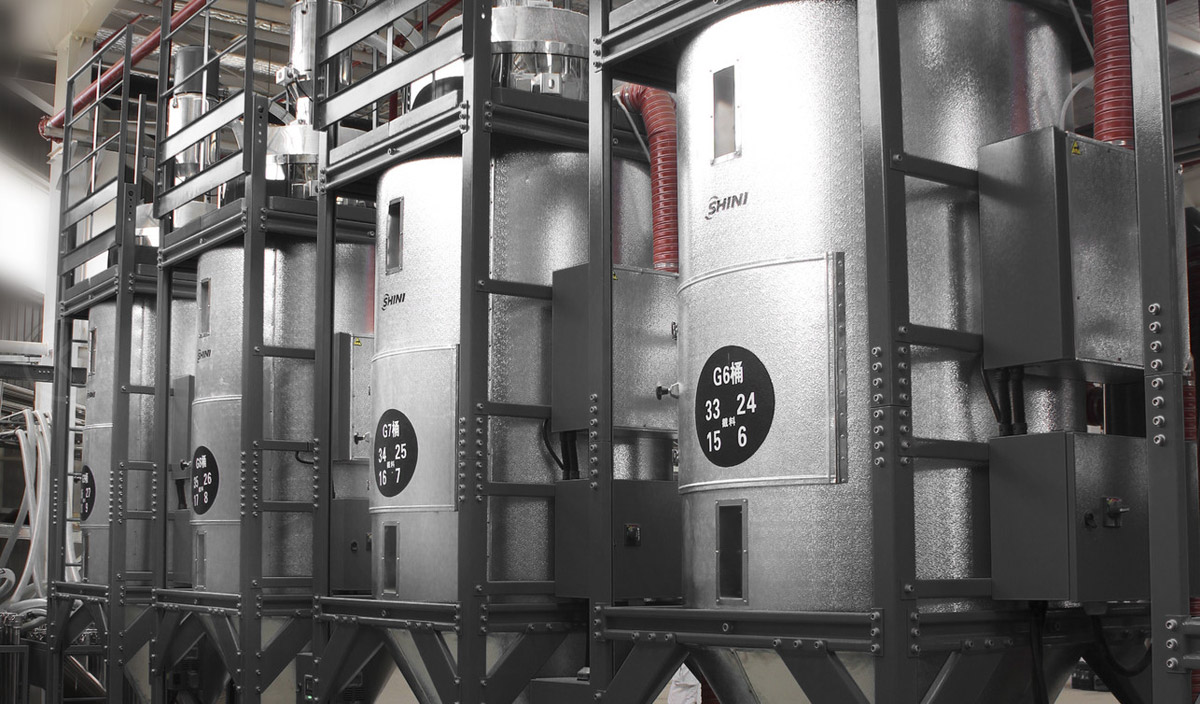

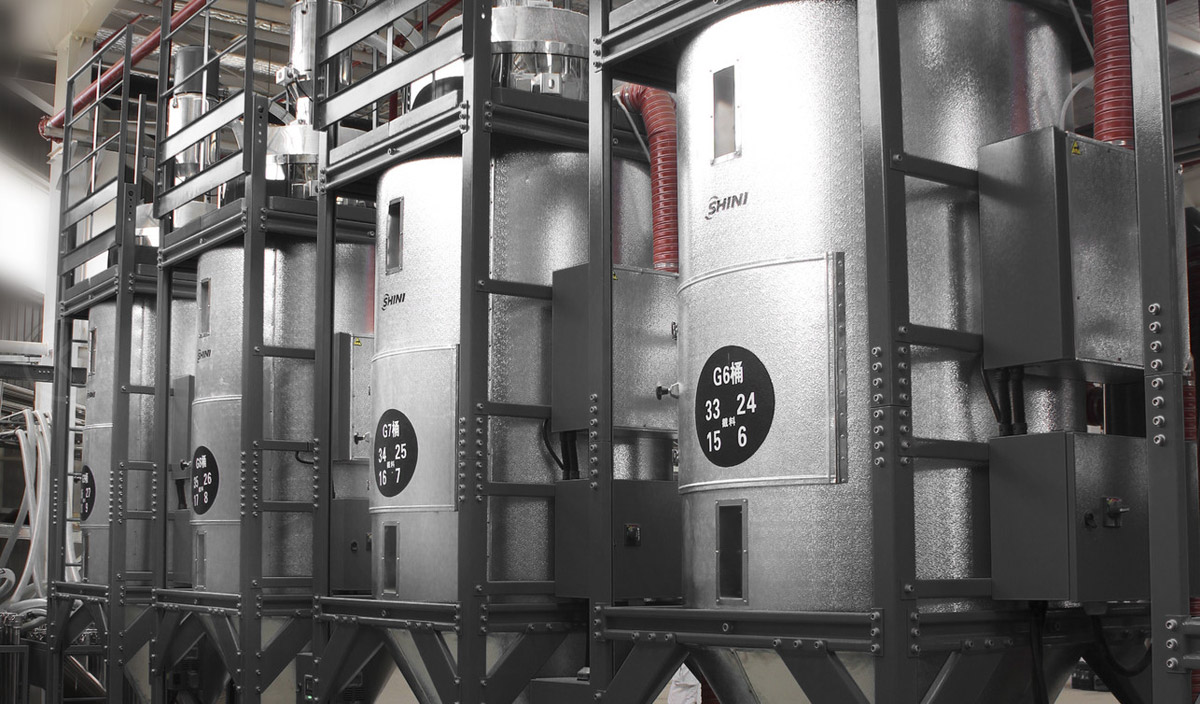

Smart Modular Dehumidifying Dryer SSMD

In addition, the Smart Modular Dehumidifying Dryer developed by Shini can always ensure that the plastic materials are in a suitable dry environment and the plastics' dryness reaches an appropriate state. The machine has a recipe function that can store all kinds of recipes according to different materials, which is very friendly to the user's parameter call. The full-touch operation can visually display various information such as drying temp., drying airflow, dew point temperature, and equipment status, and it is very convenient for the operator to use in handy.

The drying airflow of the Shini Dehumidifying Dryer can reach up to 4000m3/hr, and the max drying hopper's capacity of 8000L. That can meet the requirements of mass material processing and customize various specific functions according to actual demands.

The Application of Large Dehumidifying Dryers

Special Reports

- Advantages of the Air-cooled Drying & Dehumidifying Equipment

- Why does the granulator use the dust-separating system?

- SGB Applied in the Dosing and Mixing of Long Glass-fiber Materials

- The Application of Shut-off Suction Box

- How to choose the right micro-feeder

- Different Applications of Single-shaft Shredder and Large Granulator

- ShiniEurope

- The Origin of the SCC Cooling Consumption Monitor

If you want to read other articles, back to2022 Quarter 1 Issue 46.