Special Reports

2022 Quarter 2 Issue 47

Application of SMM Material Consumption Monitor for Hopper Receiver

Under the great tide of digitization and intellectualization, all industries daily embrace the challenges of all kinds of new ideas. For the plastic molding industry, the progress of digitalization closely follows the country or even the world trend, which puts forward effective and targeted digital solutions for the whole molding process. Most of these solutions are reflected in the integration with the lean production theory, ultimately reducing the waste and improving the productivity and management efficiency through data transparency and elimination of “information islands.” The plastic molding process accounts for a large part of the production expenses to use the plastic materials, significantly affecting the product pricing. However, in the production of existing injection molding machines and other equipment, the method of material consumption calculation is to reflect the general dosage of the silo by material level detection or estimation. This method lacks a necessary and solid data foundation, primarily relying on personnel subjective judgment, making it inconvenient to arrange proper production and check the material dosage in real-time. The operation to check the dosage details is complex, takes a certain amount of labor, and is time-consuming and laborious. In addition, there will be inaccurate calculations and errors due to human factors during the calculation process. The SMM material consumption monitor can be used with the conveying equipment to measure real-time material consumption. The data can compare the expected and actual output when necessary and adjust the production parameters of the equipment. The equipment is installed under the hopper and independently operated, which can be flexibly used in various feeding systems or single equipment.

With a standard communication interface, the SMM can upload the collected data to other host equipment (such as MES, SCADA, etc.) in real-time, compare and analyze the system data, and cooperate with the real-time material weight of the silo. It can quickly find the material consumption flow, study the material utilization condition, and formulate proper material dosage and improvement countermeasures.

Features

Application

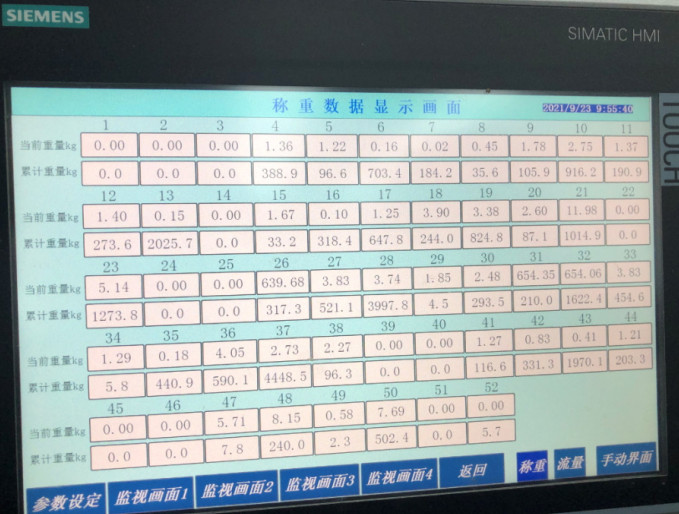

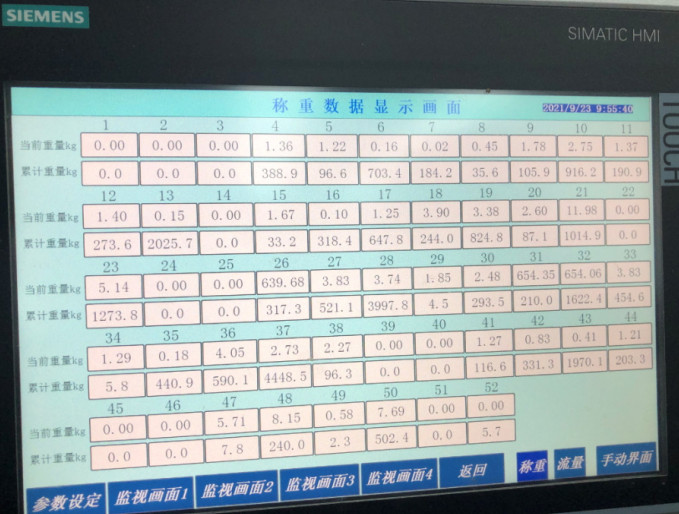

A plastic manufacturing plant in Jiangsu mainly produces inner refrigerator covers, etc. It has purchased more than 50 SMM material consumption monitors and installed them above on the storage collective hopper. After the central conveying, it will weigh the hopper, and the weighed data will be sent to the control station by the RS485 interface, which can reflect the material consumption of each machine to adjust the equipment.

With a standard communication interface, the SMM can upload the collected data to other host equipment (such as MES, SCADA, etc.) in real-time, compare and analyze the system data, and cooperate with the real-time material weight of the silo. It can quickly find the material consumption flow, study the material utilization condition, and formulate proper material dosage and improvement countermeasures.

Features

- Real-time material consumption monitoring;

- Production batch control.

- Production output record.

- The precision can reach up to ±1%;

- Material contact surfaces are made of stainless steel to ensure no material contamination.

- Mounted with the hopper and loader, suitable for self-contained hopper loader and feeding system with shut-off function.

- Standard communication function via RS485.

Application

A plastic manufacturing plant in Jiangsu mainly produces inner refrigerator covers, etc. It has purchased more than 50 SMM material consumption monitors and installed them above on the storage collective hopper. After the central conveying, it will weigh the hopper, and the weighed data will be sent to the control station by the RS485 interface, which can reflect the material consumption of each machine to adjust the equipment.

Special Reports

- Heating and Cooling Auxiliary Equipments for the Controls in Wide Temperature Ranges

- SPG Pump Group

- Advantages of Central Conveying System

- How to effectively prevent mould from being condensed in the production process?

- SDS Dry Cooler

- Why Are We Using the Material Distribution Station?

- Application of Metal Detector in Plastics Moulding Industry

If you want to read other articles, back to2022 Quarter 2 Issue 47.