Understanding Plastic Auxiliary Equipment: Its Critical Impact on Production Quality

In plastics processing, the spotlight is often on the heavy machinery: injection molding machines, extruders, and blow molders. However, the true performance of a production line often depends on the supporting systems. These plastic auxiliary systems aren’t just "accessories"—they are the foundation of a stable manufacturing process.

Without reliable plastic auxiliary equipment, even the most advanced primary machines can struggle to produce consistent, high-quality parts. This overview explores the critical role these systems play and why they’re essential to modern, cost-effective plastic manufacturing.

What Is Plastic Auxiliary Equipment?

Plastic auxiliary equipment refers to the machinery used to support the primary plastic processing equipment. While the primary machines shape the plastic, the auxiliary systems manage the crucial variables of the process: material preparation, temperature regulation, and waste recovery.

The Role of Plastic Auxiliary Systems

The main goal of auxiliary equipment is to create a stable, repeatable production environment. It ensures that:

- Resin is perfectly dry and free of moisture.

- Material is automatically conveyed to the machine throat without contamination.

- Molds maintain precise, steady temperatures.

- Scrap and sprues are immediately granulated and fed back into the process.

Without these systems, manufacturers face defects like splay marks, inconsistent dimensions, and high scrap rates. Whether in injection moulding, extrusion, or blow moulding, auxiliary equipment is the key to maximizing efficiency and product quality.

In short, plastic auxiliary equipment removes variability from the process, which is the foundation of consistent plastic manufacturing.

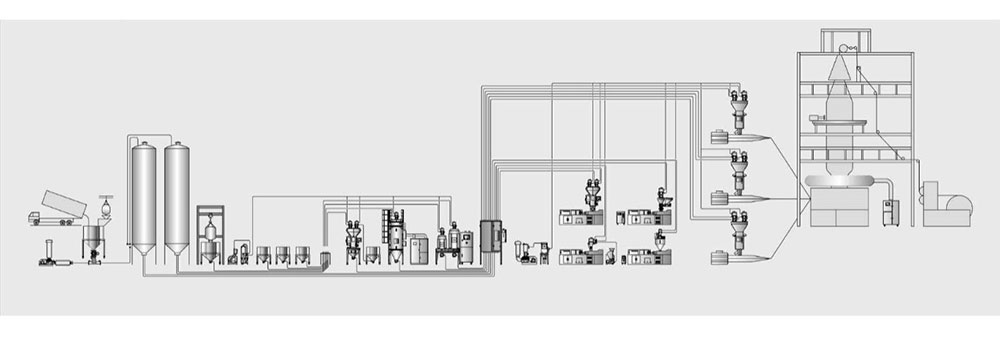

Auxiliary Equipment in the Plastic Production Workflow

A typical plastic production workflow supported by auxiliary equipment looks like this:

Material Handling → Drying → Processing Support → Heating & Cooling → Recycling

Key Stages Supported

-

Material Preparation:

Before processing, resin must be transported from silos or bags, dried to remove moisture, and blended with additives or masterbatch. -

Processing Support:

During moulding, precise temperature control is required to cool the part (via chillers) or heat the mold (via temperature controllers). -

Post-Processing:

After the part is ejected, robots may handle the product, while runners and scrap are fed into granulators for recycling.

Standalone vs. Central Systems

-

Standalone Machines:

Individual units (e.g., a hopper loader) attached to a single moulding machine. They are Ideal for smaller operations or frequent material changes. -

Central Systems:

A centralized infrastructure (e.g., a central conveying system) manages material distribution across the entire factory floor, reducing manual labor and improving plant organization.

4 Key Categories of Plastic Auxiliary Equipment for Manufacturing

Shini offers a comprehensive range of equipment covering every stage of the plastic cycle. Here are the some categories:

-

Material Drying & Dehumidifying Systems

Moisture is the enemy of plastic processing. Hydroscopic materials like ABS, PET, PC, PMMA, and PA (Nylon) absorb moisture from the air, which turns into blistering (bubbles), sink marks, and splay marks during the moulding process, causing structural defects.

-

Hopper Dryers:

The standard solution for removing surface moisture using hot air. -

Dehumidifying Dryers:

These are essential for engineering plastics. They use desiccant wheels (like Shini Honeycomb Dryers) to supply dry air with consistent low dew point (max down to -40°C or lower), ensuring deep molecular drying.

For a deeper technical explanation of drying principles and dryer selection, see the Shini technical blog - Plastic Dryers for Industrial Applications: Complete Guide.

-

-

Material Handling & Feeding Systems

Moving tons of plastic pellets manually is inefficient and messy. Automated systems provide a much cleaner, more efficient solution.

-

Vacuum Loaders:

Automatically convey material from a silos, bags, or material bins to the machine hopper. -

Central Conveying Systems:

These utilize a central vacuum pump and a network of pipes to convey materials to multiple machines over long distances, reducing manual movement of material -

Dosing & Mixing:

Equipment to ensure precise ratios of virgin material, regrind, and masterbatch.

-

-

Temperature Control & Cooling Equipment

Thermal stability is crucial for cycle time and dimensional accuracy.

-

Industrial Chillers:

These cool the mould and reduce the product cycle time. It is also used to remove heat from the hydraulic oil. Shini Chillers come in air-cooled or water-cooled variants to suit factory infrastructure. -

Mold Temperature Controllers (MTC):

These circulate water or heat transfer oil to heat the mould to a specific operating temperature, crucial for optimizing the flow of material in the mould and surface finish.

-

-

Recycling, Granulating & Regrind Systems

To minimize material costs, scrap must be reused.

-

Granulators (Crushers):

Machines that grind sprues, runners, and defective parts into small granules (regrind). -

Scrap Recovery Systems:

Shini Granulators can often be integrated directly at the machine side for immediate return of regrind into the process (instant recycling), preventing material contamination or degradation.

For more information about How to select the right Plastic Granulators? Please visit the blog How to Select Plastic Granulators?

-

How Auxiliary Equipment Improves Process Performance

Investing in high-quality auxiliary equipment brings direct returns:

-

Product Quality Consistency:

Highly automated drying, dosing, and temperature control remove human error and environmental variables, ensuring every batch meets specifications. -

Production Efficiency and Uptime:

Central conveying systems eliminate machine downtime caused by empty hoppers. Reliable chillers ensure consistent low cycle times. -

Cost Control and Energy Savings:

Modern auxiliary equipment, such as energy-saving dryers and chillers, consumes significantly less power, directly lowering operational costs.

Key Considerations When Selecting Auxiliary Equipment

Choosing the right equipment depends on your specific production needs:

-

Material Type and Throughput:

Engineering plastics (PC, PET, PMMA, PA, POM) require dehumidifying dryers, whereas general plastics (PP, PE) may only need hot air drying. Calculate your kg/hr throughput carefully. -

Process Type:

Extrusion requires continuous intake of material, while injection moulding operates in cycles. -

Energy Efficiency:

Look for equipment with energy-saving features, such as heat recovery systems or adaptive drying on dryers. -

Automation and Scalability:

Will a standalone unit suffice, or should you plan for a scalable central system? -

Maintenance:

Choose brands known for reliable design and accessible service parts, like Shini.

Common Issues & FAQs

Even with high-end machinery, unique challenges often arise on the production floor. Here are some common issues and solutions:

-

What happens if material is not dried properly?

Improper drying leads to "splay" (silver streaks), blistering (bubbles), and sink marks on the moulding part.

-

What are the signs of undersized chillers?

If your cycle times are getting longer to allow the part to cool, or if the mold temperature fluctuates during the day, your cooling capacity may be insufficient.

-

Why are central feeding systems often underestimated?

Many factories start with manual loading. However, central systems drastically reduce material spillage, dust contamination, and labor costs, often paying for themselves faster than expected.

Future Trends in Plastic Auxiliary Equipment

The future of auxiliary equipment is smart and green.

-

Energy Efficiency:

New designs focus on heat recycling and variable frequency control to minimize carbon footprints. -

Smart Monitoring (Industry 4.0):

Shini is at the forefront of this with smart Factory solutions. Auxiliary equipment is now interconnected via IoT, allowing managers to monitor energy use, dew points, and material usage in real-time from a dashboard. -

Recycling-Driven Design:

As the circular economy grows, auxiliary systems are becoming more specialized in handling PCR (Post-Consumer Recycled) materials which can be dusty or inconsistent.

Building a Stable and Efficient Plastic Processing Line

A well-designed plastic auxiliary system is not an accessory to the production line—it is its foundation. From material drying and conveying to temperature control and recycling, auxiliary equipment removes process variability and creates the stable conditions required for consistent quality, predictable cycle times, and long-term cost control.

With decades of experience in plastics processing support equipment, Shini provides a complete range of smart auxiliary solutions designed to integrate seamlessly into injection molding, extrusion, and blow molding operations. Whether you are planning a new factory or upgrading an existing line, Shini’s systems help manufacturers build scalable, energy-efficient, and future-ready production environments.

Further Technical Reading from the Shini Blog.

For readers who want to explore specific auxiliary systems in more detail, the following technical guides may be helpful:

- Plastic Dryers for Industrial Applications: A Complete Guide

- What Is Gravimetric Blending? Understanding the Process, Benefits, and Key Applications

- Batch vs. Continuous Blending: Which Method Is Right for Your Process?

- Super Features and Versatile Applications of Automated Bulk Bag Unloader

- Simple and Automated Bulk Bag Unloading System : Ease Your Plastic Material Handling Process

- How to Select Plastic Granulators?

Ready to optimize your production efficiency? Every facility has its own unique set of challenges. If you’re looking for a tailored solution to stabilize your quality or reduce operational costs, our technical experts are here to help. Visit our Contact Us page to leave a message, and let’s discuss how we can build a future-ready production line together.