Plastic Dryers for Industrial Applications: Complete Guide

In the world of plastic manufacturing, precision and reliability depend heavily on one overlooked process: plastic drying. Without proper drying, industrial plastics can suffer from bubbles, cracks, and costly defects. That’s why choosing the right industrial plastic dryer is essential for maintaining consistent product quality and lowering energy consumption. At Shini, we have supported more than 10000+ factories worldwide, helping them optimize their plastic drying process and cut production waste by up to 30%.

How Plastic Dryers Work

To choose the right drying system, it’s important to first understand how the plastic drying process works. Different technologies target moisture in different ways, and this directly affects product quality.

Plastic materials absorb moisture from the air. If not removed, this moisture can degrade the polymer during processing. Plastic dryers use different methods to remove moisture effectively:

Types of Plastic Dryers

There is no one-size-fits-all solution in industrial plastic drying. Each dryer type is designed for specific materials and production needs. Below are the most common systems used in modern factories.

-

Hopper Dryer

A hopper dryer (or hot air dryer) is widely used in injection molding and extrusion. It offers cost-effective drying by blowing hot air through plastic granules inside a hopper.

-

Energy Saving Hopper Dryer

A Energy Saving hopper dryer (or energy saving hot air dryer) is a new generation of hot air dryer used in injection molding and extrusion. It offers cost-effective drying by managing effective drying via inverter control blower. It blows the right among of hot air through plastic granules inside a hopper.

-

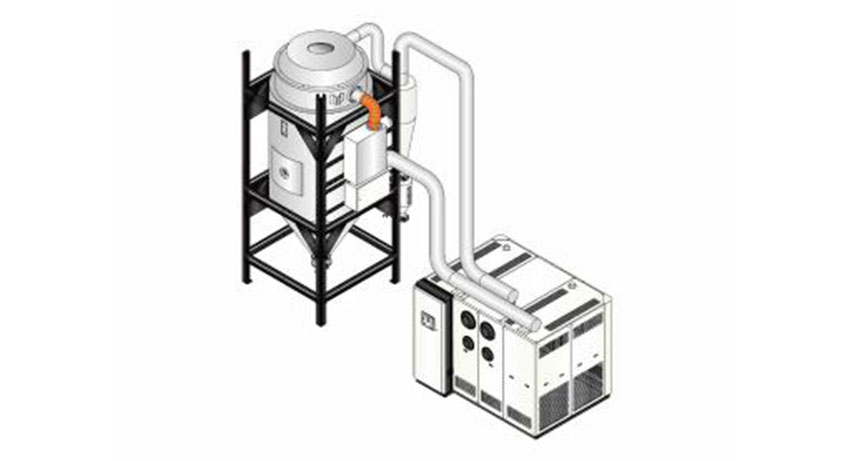

Desiccant Dryer

A desiccant dryer (or dehumidifing dryer) is indispensable for engineering plastics like PET, PC, and nylon. It delivers ultra-low dew point air for high-precision applications.

-

Energy Saving Desiccant Dryer

A energy saving desiccant dryer (or energy saving dehumidifing dryer) is indispensable for engineering plastics like PET, PC, and nylon with minial energy used. It a new generation drying control and inverter to delivers right amount of low dew point air.

Comparison of Plastic Dryers

Once the dryer types are clear, the next step is to compare their performance. The following table highlights differences in cost, energy use, and applications, making it easier to evaluate the right option.

| Dryer Type | Best For | Energy Use | Cost | Applications |

|---|---|---|---|---|

| Hopper Dryer | Injection / Extrusion | High | Low | General plastics |

|

Energy Saving Hopper Dryer |

Injection / Extrusion | Low | Medium | General plastics |

| Desiccant Dryer | Engineering resins (PET) | High | Medium | High-precision molding |

| Energy Saving Desiccant Dryer | Engineering resins (PET) | Low | High | Engineering plastic with low energy consumption. |

While these comparisons give a technical overview, nothing illustrates the benefits of proper plastic drying better than a real-world case study.

Case Study: Industrial Plastic Drying for PET Bottles

A PET bottle manufacturer in Southeast Asia struggled with moisture-related defects that increased scrap rates. By upgrading to the Shini SDD Industrial Plastic Dryer, the factory reduced moisture content from 0.12% to 0.02%. This improvement not only enhanced clarity and durability but also lowered defect rates by 25% within three months, proving the importance of reliable plastic drying solutions in large-scale production.

Applications in Industry

Different industries rely on industrial plastic dryers in unique ways. From injection molding to recycling, dryers play a critical role in ensuring efficiency and quality.

- Injection Molding: Resin dryers ensure hygroscopic resins are perfectly dry before molding.

- Extrusion: Hopper dryers and hot air dryers keep continuous production stable.

- Recycling: Plastic pellet dryers and centrifugal dryers prepare recycled materials for reuse, often working together with plastic granulators to ensure consistent size reduction and drying efficiency.

Read More: Batch vs. Continuous Blending: Which Method Is Right for You? to compare how blending methods integrate with different plastic drying systems.

Buying Guide: Choosing the Right Plastic Dryer

With so many dryer types available, the key question becomes: which one is right for your production line? The following guide will help you make a decision based on material type, energy use, and cost considerations.

- Material type – Is it hygroscopic or non-hygroscopic? In many factories, dryers are paired with bulk bag unloaders to streamline raw material handling before drying.

- Moisture level – How much drying is required?

- Energy efficiency – Does the dryer fit your operational budget?

- Cost and maintenance – Balancing initial investment with long-term savings.

FAQs

Below are some of the most common questions engineers and manufacturers ask when evaluating plastic drying systems.

-

What is the best dryer for plastic pellets?

Energy Saving hopper dryer.

-

Hopper dryer vs desiccant dryer?

Hopper dryers are cost-effective for general plastics, desiccant dryers are essential for engineering resins.

-

How much energy does a plastic dryer consume?

Varies by type; energy saving dryer consume less energy via drying control formula and inverter.

-

How can I reduce energy consumption when using hopper dryers?

Choose models with energy saving, inverter and dew-point monitoring, which can cut energy use by up to 60% compared to traditional dryers.

Shini Solutions

As an industry leader, Shini offers a full range of industrial plastic dryers and dehumidifiers, along with plastic material handling equipment to support complete factory automation.

-

Hopper Dryers (SHD Series)

: Cost-effective hot air drying for general plastics. -

Desiccant Dryers (SDD, SCD)

: Ultra-low dew point systems for engineering plastics such as PET, PC, and Nylon. -

Specialized Solutions

: PET crystallizers (SCR), nitrogen dryers (SND), and mould sweat dehumidifiers (SMD-H). -

Energy-saving Controllers (SEC-H, SEC-U)

: Smart systems to optimize drying performance.

Request a catalog or contact our engineers to find the right Hopper Dryer for your production line.